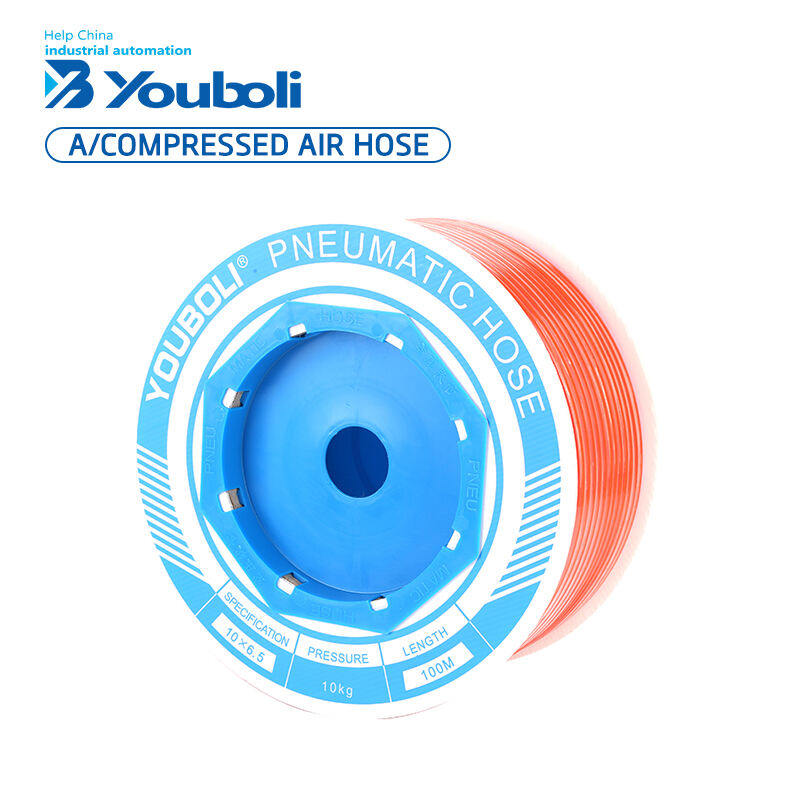

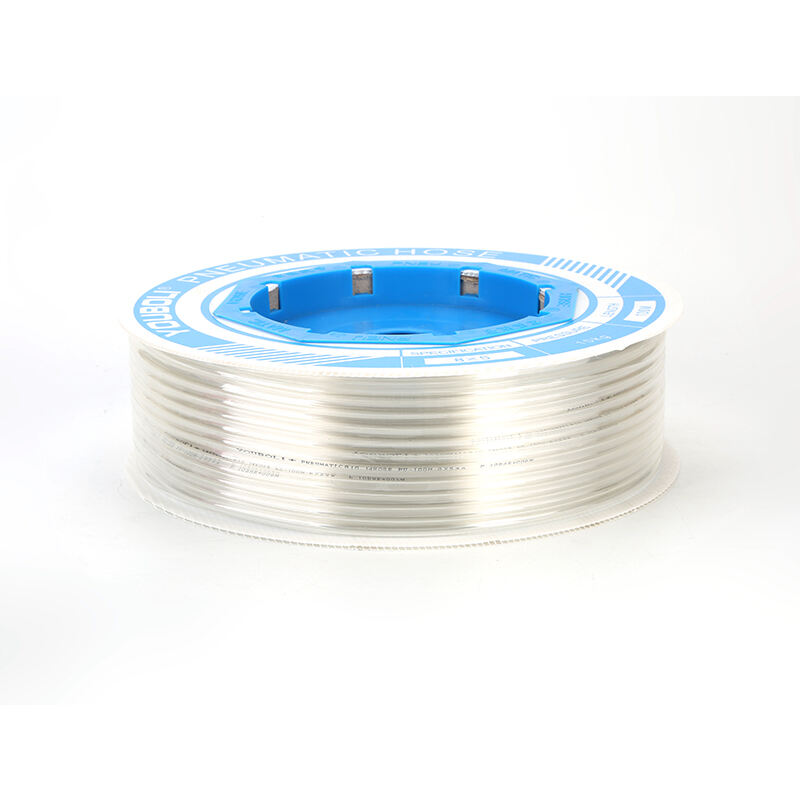

air compressor hoes

Air compressor hoses are essential components in pneumatic systems, serving as the crucial link between the compressor unit and pneumatic tools or equipment. These specialized hoses are engineered to withstand high pressure conditions while maintaining flexibility for ease of use. Modern air compressor hoses are typically constructed using durable materials such as rubber, PVC, or hybrid polymers, enabling them to handle pressures ranging from 100 to 300 PSI depending on their specific design. The inner core of these hoses features smooth walls to minimize friction and ensure optimal air flow, while the outer layer provides protection against abrasion, UV exposure, and various workplace chemicals. They come in various lengths, typically ranging from 25 to 100 feet, and different diameters to accommodate different air flow requirements. The end fittings are designed with quick-connect couplings that allow for rapid tool changes while maintaining an airtight seal. Advanced models incorporate features such as self-retracting mechanisms, kink-resistant construction, and temperature-resistant materials, making them suitable for both industrial applications and DIY projects.