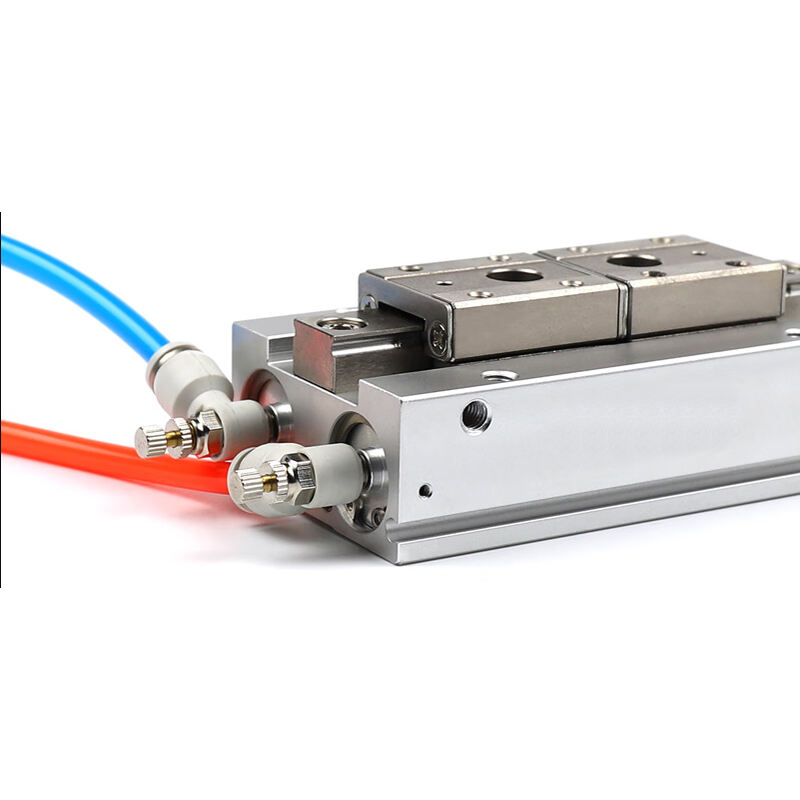

a cylinder

A cylinder is a fundamental mechanical component that serves as a crucial element in various hydraulic and pneumatic systems. This versatile device consists of a piston that moves within a cylindrical chamber, converting fluid pressure into linear mechanical force. The basic structure includes a hollow cylinder barrel, a piston, seals, and end caps, working together to create controlled linear motion. Modern cylinders incorporate advanced features such as precision-engineered seals, wear-resistant materials, and sophisticated position sensing technology. These components are designed to operate in diverse environments, from industrial manufacturing to mobile equipment applications. Cylinders can be categorized into single-acting and double-acting types, each serving specific operational requirements. They are essential in applications requiring precise linear motion control, force application, and mechanical power transmission. The technology behind cylinders continues to evolve, with innovations in materials science and design engineering leading to improved performance, durability, and efficiency. These improvements include enhanced sealing systems, optimized fluid dynamics, and integration with smart control systems for precise operation.