hollow cylinder

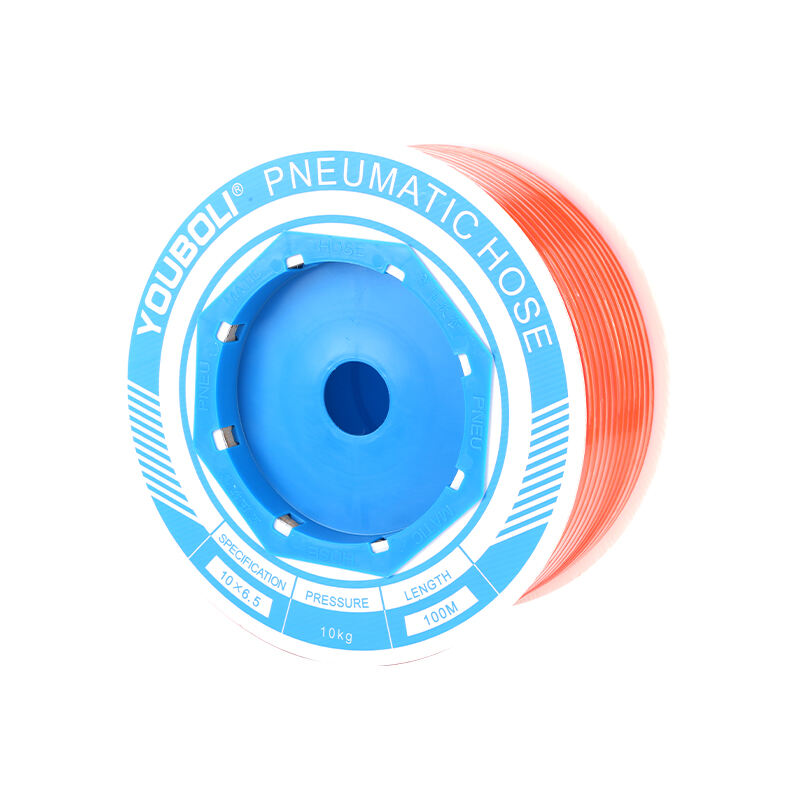

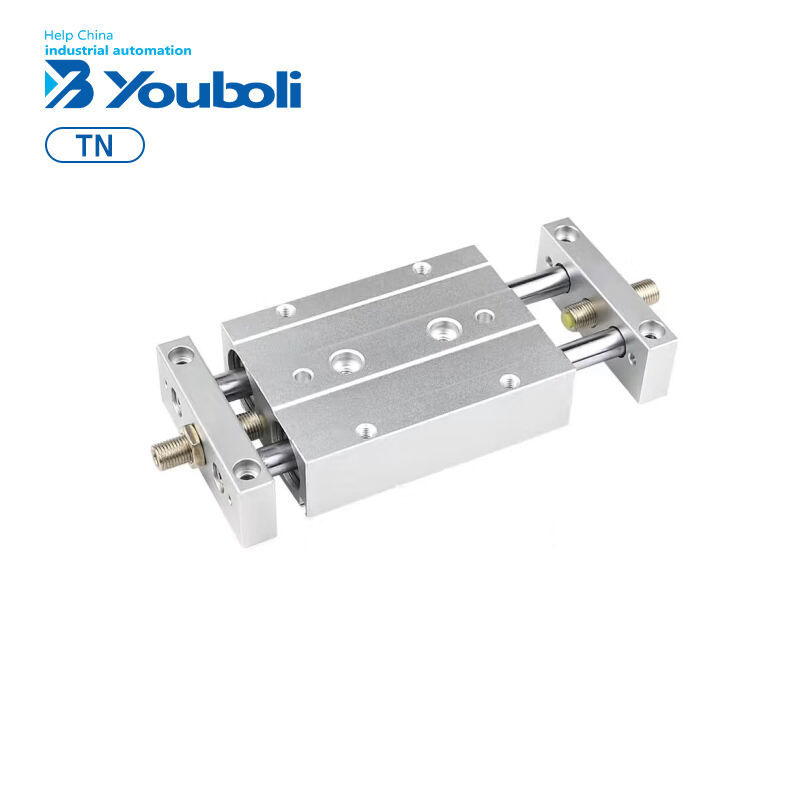

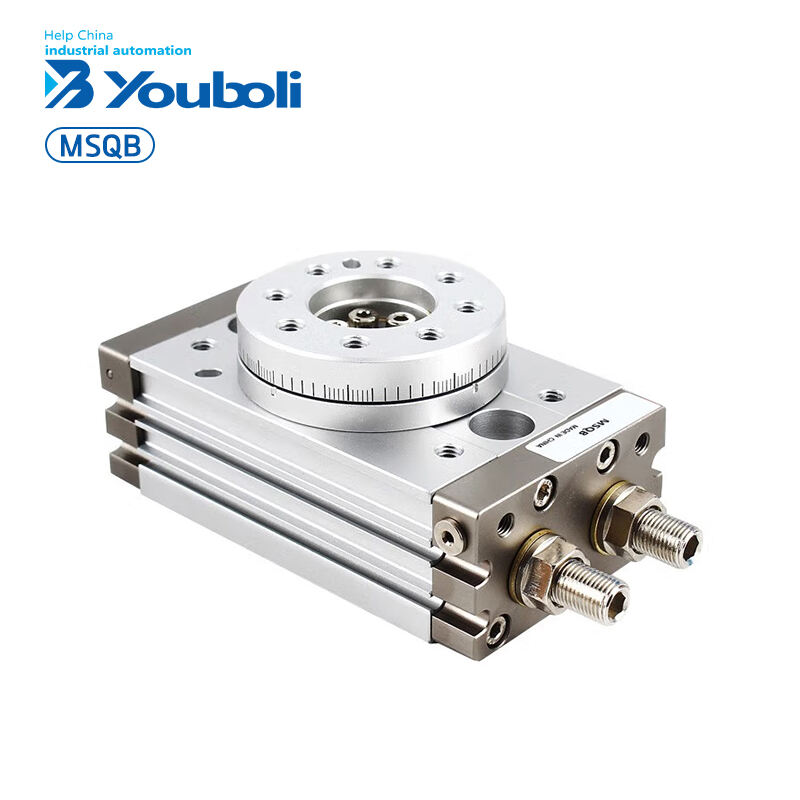

A hollow cylinder is a fundamental geometric structure characterized by its cylindrical shape with an empty internal space running through its length. This versatile component plays a crucial role in various industrial applications, engineering projects, and manufacturing processes. The design consists of two concentric cylinders of different diameters, creating an annular space that serves multiple purposes. The wall thickness, length, and diameter ratios can be customized to meet specific requirements, making it highly adaptable for different applications. In engineering, hollow cylinders are extensively used in fluid transport systems, structural supports, and mechanical components. Their design allows for optimal material distribution, providing excellent strength-to-weight ratios while minimizing material usage. The internal void space can serve as a conduit for fluids, gases, or other materials, making them essential in plumbing, HVAC systems, and industrial processing. Additionally, hollow cylinders often incorporate specific surface treatments or coatings to enhance their performance characteristics, such as corrosion resistance, thermal insulation, or wear resistance. Modern manufacturing techniques, including precision machining and advanced casting methods, ensure consistent quality and dimensional accuracy in hollow cylinder production.