Introduction

Have you ever spent hours meticulously designing a dynamic model—perhaps a steampunk-inspired mechanical dragon or a sci-fi-themed automatic door—only to have it fall short due to selecting the wrong size air cylinder? Those wings that should have beat majestically now flap weakly, and the hatch that should have slid open smoothly now stutters and jams. In the world of model building, choosing the wrong size air cylinder is one of the most common and frustrating causes of project failure.

Selecting the right air cylinder isn’t a game of guesswork. It’s a precise science that directly determines the vitality, reliability, and overall success of your creation. Whether you’re a seasoned hobbyist or just stepping into this exciting field, this guide will serve as your one-stop resource.

This article will delve into how to choose the perfect size air cylinder for your scale model projects. We’ll start with the fundamentals and guide you through a clear, actionable decision-making process. You’ll learn key calculation methods, understand the pros and cons of different sizes, and gain practical tips from within the industry. After reading, you’ll be confident in selecting cylinders that bring your creations to life exactly as imagined.

Why Cylinder Size is So Critical: It’s More Than Just Power

The importance of cylinder size cannot be overstated. It’s far more than just ensuring the cylinder fits physically within your design; it’s the beating heart of your project, directly impacting performance, safety, and user experience.

The Core of Performance and Efficiency

A correctly sized cylinder efficiently converts compressed air energy into precise, controlled mechanical motion. Conversely, an improperly sized cylinder leads to a host of issues:

Too Small: The cylinder will lack the force needed to move the load, resulting in sluggish, weak movement, or even complete stall under pressure. It will struggle constantly, consuming more air than necessary, putting undue strain on your air system.

Too Large: Often thought of as the "safe" choice, this also has negative consequences. An oversized cylinder can be sluggish, slow, and requires more compressed air to operate, reducing overall system efficiency. In precision models where space is limited, it can also lead to bulky and inelegant designs.

Safety and Longevity

For projects involving moving parts, especially those that might be handled by children, safety is paramount.

An underpowered (undersized) cylinder may stall or fail under load, leading to unpredictable behavior.

An overpowered (oversized) cylinder, if not properly controlled, can move too violently, causing damage to the model itself or to the user.

The right size ensures smooth, controlled motion, protecting your intricate work and ensuring its long-term reliability.

Scale and Realism

In model making, authenticity is key. A cylinder that is overly large and clumsy relative to your creation shatters the illusion. Choosing the right size helps maintain proportional integrity, ensuring movement looks natural and fits the model’s narrative, whether it's the flick of a miniature dinosaur's tail or the powerful lift of a large crane model.

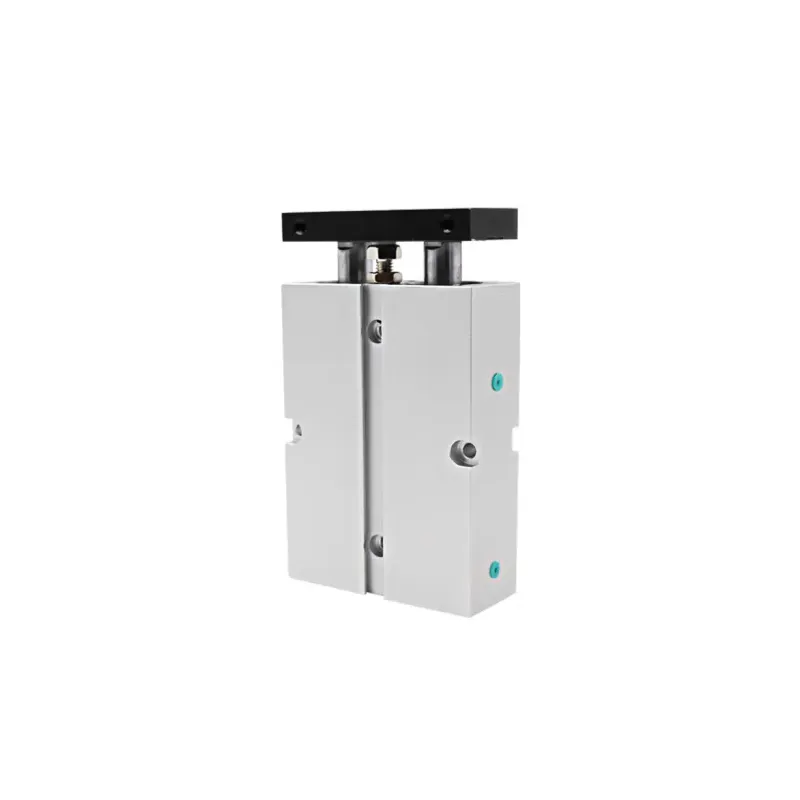

Understanding the Basics: What "Size" Really Means in Air Cylinders

Before we dive into the selection process, let's clarify what we actually mean when we discuss cylinder "size." It’s not primarily a single measurement but a combination of two key specifications:

Bore Diameter

What it is: The inner diameter of the cylinder barrel. It is essentially the diameter of the piston.

What it controls: Force. This is the most critical factor. The force a cylinder generates is directly related to the area of the piston, which is determined by the bore. The calculation formula is:

Force (F) = Pressure (P) × Area (A)

For a double-acting cylinder, Area (A) is πr² (where r is the radius of the bore).Unit of Measure: Most commonly expressed in millimeters (mm). In toys and models, you'll typically encounter bores ranging from a tiny 2mm to a more substantial 20mm or larger.

Stroke

What it is: The distance the piston travels inside the cylinder. It determines how far the cylinder rod can extend.

What it controls: Range of motion. It defines how far your mechanism—whether an arm, door, or lever—can move.

Unit of Measure: Millimeters (mm). Stroke length can vary greatly based on your specific needs.

So, when you are selecting "size," you are actually choosing both the bore (for force) and the stroke (for distance). A cylinder might be specified as "10mm bore x 20mm stroke."

How to Choose the Perfect Size for Your Model: A Step-by-Step Guide

Now for the practical part. Follow this systematic process to determine the ideal cylinder for your next project.

Step 1: Define Your Application Requirements

Start by getting clear on what you want the cylinder to do. Get out a notebook and answer these questions:

What does it need to move? (e.g., a 200-gram robotic arm, a 0.5 kg hatch door)

What action does it need to perform? (Push, pull, lift, rotate?)

How far does it need to move? (Measure the required full range of motion in mm precisely—this is your stroke length).

How fast does it need to move? (Speed is controllable but influenced by cylinder size and airflow).

What are the space constraints? (What is the physical space available for the cylinder in LxWxH? Take a picture of your model's bay and note the dimensions).

Step 2: Calculate the Required Force

This is the most critical calculation. You need to ensure the force generated by the cylinder exceeds the force required to move the load.

-

Determine the Load Force (F_load): This is the force needed to move your component. For models, this often includes:

Friction: The force of friction as the part slides on rails or pivots on hinges.

Gravity: If the cylinder is lifting the load vertically, you must overcome gravity. Gravity = Mass (kg) x Gravitational Acceleration (9.8 m/s²). For horizontal movement, this is often negligible.

Safety Factor (SF): Always add a safety factor to account for friction losses, air pressure fluctuations, or calculation errors. For models, an SF of 1.5 to 2 is a good starting point.

Formula: Required Force = [Load Force (F_load) + Gravity (if applicable)] x Safety Factor (SF)

Example: If you are vertically lifting a component with a mass of 0.3 kg (300 g) and estimate friction at 2N.

Gravity = 0.3 kg * 9.8 m/s² = 2.94 N

Total Load Force = 2.94 N + 2 N = 4.94 N

Apply Safety Factor (1.5): Required Force = 4.94 N * 1.5 = ~7.5 N

-

Calculate Available Cylinder Force Based on Available Pressure:

You need to know what pressure your air supply can provide (e.g., a standard model compressor or tank might provide 60-100 PSI or 4-7 bar).Formula: Cylinder Force (F) = Pressure (P) x Area (A)

Ensure units are consistent! Convert PSI to Bar (1 Bar ≈ 14.5 PSI) or mm to cm for calculation.

Area (A) = π * r² | (r = bore radius).

Simplified Example: Using a pressure of 5 bar and a cylinder with a 10mm bore.

Radius = 5mm = 0.5 cm

Area (A) = 3.14 * (0.5 cm)² = 0.785 cm²

Force (F) = 5 bar * 0.785 cm² = 3.925 N (since 1 bar ≈ 1 N/cm²)

In this example, 3.9N of force < 7.5N of required force. Therefore, the 10mm bore is underpowered at 5 bar. You would need a larger bore (e.g., 15mm) or higher pressure.

Step 3: Consult a Sizing Chart

For simplification, here is a quick reference table showing the approximate output force for common model cylinder bores at 5 bar (72.5 PSI) pressure. This is a great starting point.

| Bore Size | Approx. Output Force (at 5 bar) | Typical Applications in Models |

|---|---|---|

| 2mm - 5mm | 0.2N - 2.5N | Micro-actions: Triggering release mechanisms, moving very light levers, popping small panels. |

| 6mm - 10mm | 2.5N - 10N | Light to medium duty: Operating scale car doors, hatches, small robotic arms, minor limbs on animatronic figures. |

| 12mm - 16mm | 11N - 25N | Medium duty: Lifting heavier arms, moving small vehicles, primary actions in medium mechanical models. |

| 20mm+ | 25N+ | Heavy duty: Primary neck/tail motion in large model dinosaurs, heavy lifts, industrial models requiring significant force. |

Table 1: Cylinder Bore Selection Guide

Step 4: Finalize Stroke and Mounting Type

Stroke: Select this directly based on the required range of motion you measured in Step 1. When in doubt, a slightly longer stroke is often more workable than a shorter one, as you can mechanically limit the movement, but you can't create movement that isn't there.

-

Mounting Type: How will it attach to your model? Common types include:

Trunnion Mount: Allows the cylinder to pivot on a point, good for arcing motions.

Threaded Ends: Screw directly into components, ideal for straight push-pull motions.

Flange Mount: Provides a very rigid, immovable mounting point, suitable for applications with high side loads.

Choose a mount that supports your type of motion and works within the available space.

Weighing the Pros and Cons: An In-Depth Look at Common Cylinder Sizes

Understanding the trade-offs of different size ranges helps make an informed decision.

Small Cylinders (<10mm Bore)

-

Pros:

Space-Efficient: Perfect for extremely compact spaces and micro-models.

Low Air Consumption: Uses minimal air per cycle, allowing for smaller reservoirs or longer run times.

High Speed: Can often achieve faster cycle times.

-

Cons:

Limited Force Output: Can only handle the lightest tasks.

Sensitive to Load: Extra friction or unaccounted weight can easily cause failure.

Best For: Delicate detail work, release mechanisms, and lightweight 1:24 scale and above models.

Medium Cylinders (10mm - 16mm Bore)

-

Pros:

Force-Size Balance: Offers the best balance, suitable for the widest range of model applications.

Widely Available: The most common size, available from various manufacturers with multiple mounting options.

Versatile: Can handle everything from functional doors to robotic arms.

-

Cons:

Can be Sluggish: If oversized for the application, can seem bulky or slow.

Best For: Most general-purpose uses: robot arms, vehicle hatches, actions in 1:12 scale figures, medium mechanical sculptures.

Large Cylinders (20mm+ Bore)

-

Pros:

High Power: Delivers the most force, capable of moving heavy weights and tackling demanding tasks.

Robust and Reliable: Often built to be more durable.

-

Cons:

High Air Consumption: Requires a significant volume of air per cycle, necessitating larger compressors and reservoirs.

Slower Speed: Accelerating the larger mass takes more time, can result in slower movement.

Space Hog: Can dominate the small compartments of a model.

Best For: Large sculptures, heavy-duty industrial models, displays requiring simulated great force, and primary actions in large-scale models (e.g., 1:6 scale).

Expert Tips and Common Pitfalls

Use Flow Control Valves: Always install flow control valves on your cylinders. These allow you to finely tune the air flow in and out, giving you precise control over speed. Without these, your movements can be jerky and unstable.

Consider "Soft" Start/Stop: For more realistic movement, use cylinders with built-in cushioning or add external stops to prevent the mechanism from "banging" at the end of its stroke.

Test Your Pressure: Don't assume your system pressure in calculations. Measure it with a pressure gauge! Battery-powered compressors can drop in pressure as they drain.

Prototyping is Key: Always build a simple mock-up with cardboard or 3D-printed parts to test your cylinder choice before committing to the final model. This is the best way to avoid costly mistakes.

Don't Forget Maintenance: Even micro-cylinders need clean, dry air to prevent internal damage. A small in-line filter/regulator combo is a worthwhile investment.

Conclusion: Precise Power for Animated Creations

Choosing the right size air cylinder for your scale model might seem daunting at first, but by breaking it down into simple steps—define the need, calculate the force, select the bore and stroke—it becomes a manageable, even enjoyable, engineering exercise.

Remember, the goal isn't to pick the biggest or smallest cylinder, but the right one. A correctly sized cylinder will work silently and efficiently, turning your model's inner workings into seamless, realistic motion that captivates audiences and ignites the imagination.

Now, approach your next project with this knowledge. Measure, calculate, and watch your creation come to life with just the right amount of force.

Table of Contents

- Introduction

- Why Cylinder Size is So Critical: It’s More Than Just Power

- Understanding the Basics: What "Size" Really Means in Air Cylinders

- How to Choose the Perfect Size for Your Model: A Step-by-Step Guide

- Weighing the Pros and Cons: An In-Depth Look at Common Cylinder Sizes

- Expert Tips and Common Pitfalls

- Conclusion: Precise Power for Animated Creations