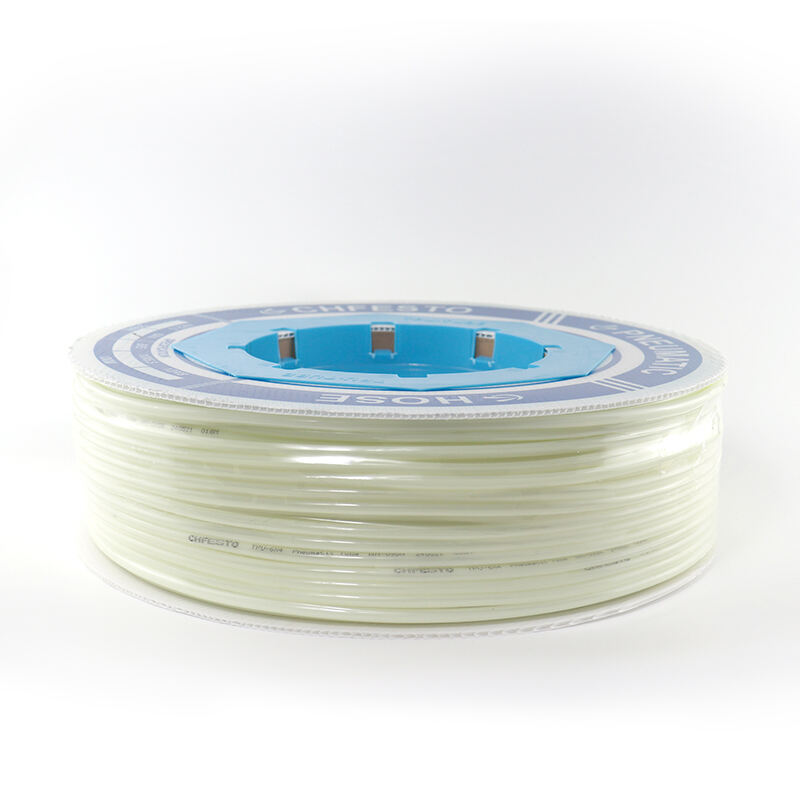

quick connect coupling hose

Quick connect coupling hoses represent a significant advancement in fluid transfer technology, offering a seamless and efficient solution for various industrial and commercial applications. These innovative devices consist of two main components: a male plug and a female socket, engineered to connect and disconnect rapidly without the need for specialized tools. The design incorporates precision-engineered locking mechanisms and sealing elements that ensure leak-free connections while maintaining system pressure integrity. These couplings are manufactured using high-grade materials such as brass, stainless steel, or durable thermoplastics, making them suitable for diverse operating environments. The internal valve design automatically shuts off flow when disconnected, preventing fluid loss and maintaining system cleanliness. Quick connect coupling hoses are available in various sizes and configurations to accommodate different pressure ratings, temperature ranges, and fluid types. They feature enhanced safety mechanisms, including double-locking systems and visual connection indicators, ensuring secure attachment and preventing accidental disconnection during operation. The versatility of these couplings extends across multiple industries, from manufacturing and automotive to agriculture and construction, where rapid connection and disconnection capabilities are essential for operational efficiency.