Understanding the Versatility of TPU Tubing in Modern Manufacturing

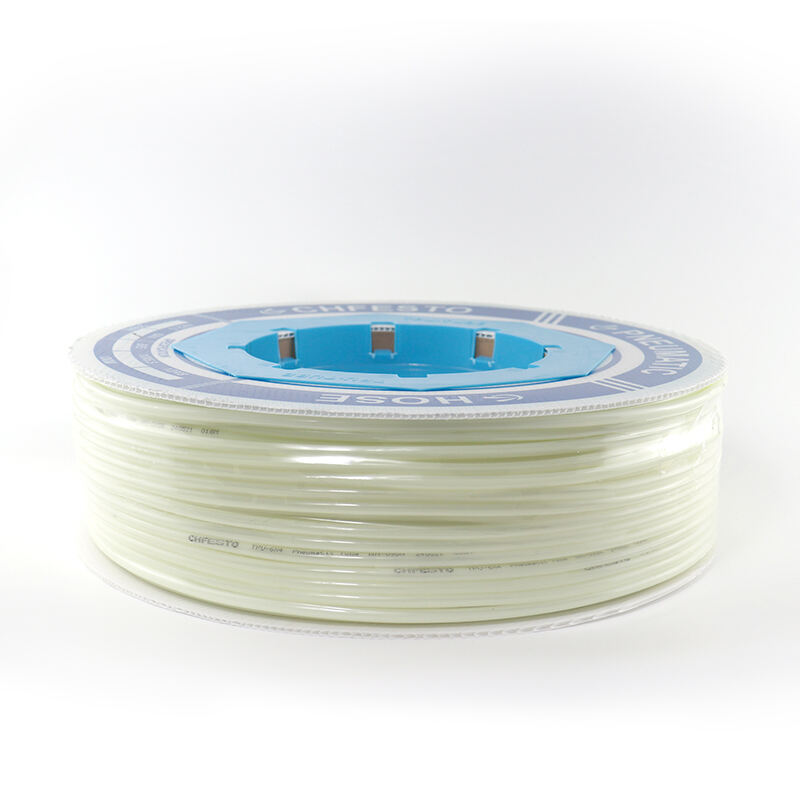

Thermoplastic polyurethane (TPU) tubing has emerged as an indispensable component across numerous industrial applications, offering a unique combination of flexibility, durability, and chemical resistance. This versatile material has revolutionized fluid transfer systems and continues to find new applications as technology advances. From automotive manufacturing to medical devices, TPU tubing plays a crucial role in ensuring efficient and reliable operations.

The remarkable properties of TPU tubing, including its exceptional wear resistance, high elasticity, and transparency, make it an ideal choice for diverse industrial processes. As industries evolve and demand more sophisticated solutions, the applications of TPU tubing continue to expand, demonstrating its adaptability and essential role in modern manufacturing.

Industrial Applications and Sectors

Automotive Industry Integration

The automotive sector extensively utilizes TPU tubing in various systems throughout vehicle manufacturing. Fuel lines, brake systems, and pneumatic controls all benefit from the material's resistance to oils, fuels, and other automotive fluids. TPU tubing's flexibility allows it to be routed through tight spaces in engine compartments while maintaining its structural integrity under varying temperatures and pressures.

Modern vehicles also incorporate TPU tubing in their air conditioning systems and windshield washer fluid delivery mechanisms. The material's ability to withstand vibration and maintain its shape makes it perfect for these dynamic automotive applications, ensuring long-term reliability and performance.

Medical and Pharmaceutical Applications

In the medical field, TPU tubing serves critical functions in various devices and equipment. Its biocompatibility and sterilization capabilities make it suitable for fluid transfer in medical devices, drug delivery systems, and diagnostic equipment. The crystal-clear nature of TPU tubing allows medical professionals to monitor fluid flow and detect any potential issues easily.

Pharmaceutical manufacturing processes also rely heavily on TPU tubing for precise fluid handling and transfer operations. The material's resistance to bacterial growth and easy cleaning properties make it ideal for maintaining the sterile conditions required in pharmaceutical production.

Manufacturing and Processing Benefits

Enhanced Production Efficiency

Manufacturing facilities benefit from TPU tubing's durability and ease of installation. The material's flexibility allows for quick setup and modifications in production lines, reducing downtime and increasing overall efficiency. Its resistance to abrasion and wear means less frequent replacement, leading to lower maintenance costs and improved productivity.

The material's ability to maintain its properties under various environmental conditions ensures consistent performance throughout manufacturing processes. This reliability is crucial for maintaining quality control and meeting production schedules in modern industrial settings.

Cost-Effective Solutions

While the initial investment in TPU tubing may be higher than some alternatives, its longevity and durability make it a cost-effective choice in the long run. The reduced need for replacement and maintenance translates to significant savings over time, making it an economically sound choice for industrial applications.

Additionally, TPU tubing's versatility often allows manufacturers to standardize their tubing requirements, reducing inventory complexity and associated costs. This standardization can lead to bulk purchasing opportunities and simplified maintenance procedures.

Environmental Considerations and Sustainability

Eco-Friendly Properties

TPU tubing aligns with modern sustainability goals through its recyclability and potential for reuse. Many manufacturers are now focusing on environmentally responsible practices, and TPU tubing's ability to be recycled makes it an attractive option for environmentally conscious industries.

The material's durability also contributes to sustainability by reducing waste generation through less frequent replacement needs. This longevity helps industries minimize their environmental impact while maintaining high performance standards.

Future Sustainable Developments

Research continues into developing even more environmentally friendly TPU tubing variants. Manufacturers are exploring bio-based materials and improved recycling methods to further reduce the environmental impact of industrial tubing applications.

The industry is also investigating ways to optimize TPU tubing production processes to reduce energy consumption and minimize waste, contributing to a more sustainable manufacturing future.

Frequently Asked Questions

What makes TPU tubing different from other types of industrial tubing?

TPU tubing stands out due to its unique combination of flexibility, durability, and chemical resistance. Unlike other materials, it offers superior wear resistance while maintaining excellent elasticity, making it ideal for various industrial applications. Its transparency and ability to withstand extreme conditions also set it apart from alternative tubing materials.

How long does TPU tubing typically last in industrial applications?

The lifespan of TPU tubing varies depending on the specific application and operating conditions, but it generally offers exceptional longevity compared to other materials. Under normal operating conditions, TPU tubing can last several years while maintaining its key properties. Regular maintenance and proper installation can further extend its service life.

Can TPU tubing be customized for specific industrial needs?

Yes, TPU tubing can be customized in terms of size, wall thickness, color, and other specifications to meet specific industrial requirements. Manufacturers can adjust the material's properties during production to enhance certain characteristics like chemical resistance or flexibility, making it suitable for specialized applications across various industries.