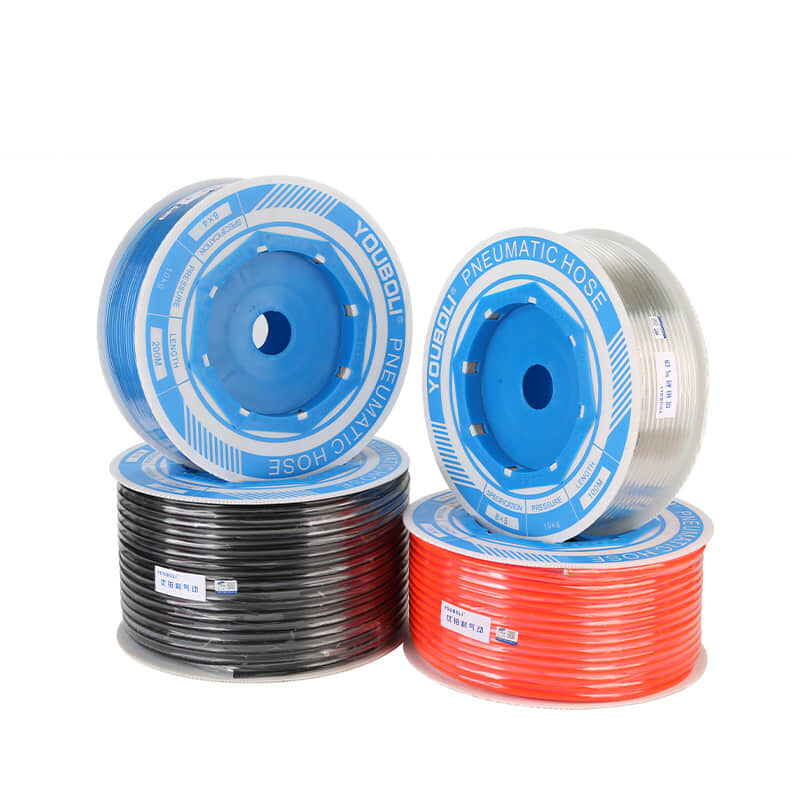

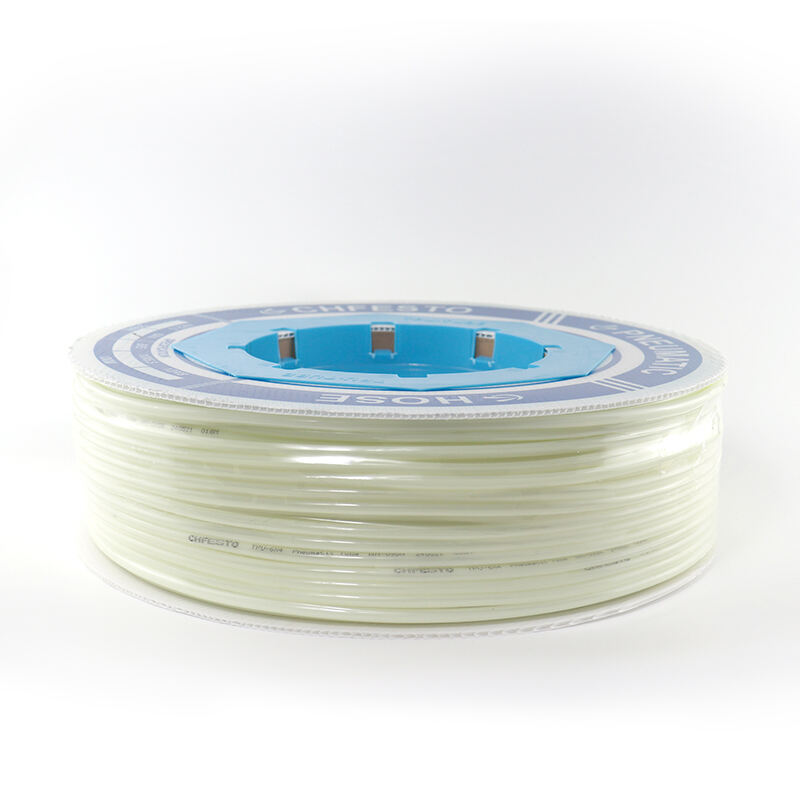

best quick connect hose fittings

Quick connect hose fittings represent a revolutionary advancement in fluid handling technology, offering seamless connectivity and reliable performance across various applications. These innovative fittings feature precision-engineered components that enable instant, secure connections without the need for tools or complex installation procedures. The design typically incorporates a self-sealing valve mechanism that automatically prevents fluid leakage when disconnected, ensuring clean and efficient operations. Made from high-grade materials such as brass, stainless steel, or durable composites, these fittings are built to withstand diverse environmental conditions and maintain integrity under varying pressure levels. They commonly feature a push-to-connect design with an internal locking mechanism that provides audible and tactile confirmation of proper engagement. The fittings are available in various sizes and configurations to accommodate different hose types and applications, from industrial manufacturing to residential garden use. Advanced models often include additional safety features such as double-lock mechanisms and color-coding systems for easy identification and prevention of cross-connection errors.