Understanding the Revolutionary World of TPU Tubing

In the ever-evolving landscape of industrial materials, TPU tubing has emerged as a game-changing solution that combines flexibility, durability, and versatility. Thermoplastic polyurethane (TPU) tubing represents a significant advancement in fluid transfer technology, offering unique properties that make it indispensable across numerous industries. From medical devices to automotive applications, TPU tubing continues to set new standards in performance and reliability.

The remarkable characteristics of TPU tubing stem from its molecular structure, which combines hard and soft segments to create a material that exhibits both elastomeric properties and processing versatility. This unique composition allows for an exceptional balance of physical properties that traditional tubing materials simply cannot match.

Essential Properties of TPU Tubing Materials

Chemical and Physical Characteristics

TPU tubing demonstrates outstanding resistance to oils, greases, and many common chemicals, making it ideal for demanding industrial environments. The material's inherent flexibility allows it to maintain its performance even under repeated bending and flexing, while its excellent tensile strength ensures long-term durability. The smooth interior walls of TPU tubing facilitate optimal flow characteristics, reducing the risk of material buildup and ensuring consistent performance over time.

Another notable characteristic is TPU tubing's exceptional wear resistance, which significantly extends its operational lifespan compared to conventional alternatives. The material's ability to withstand abrasion and impact makes it particularly valuable in applications involving continuous movement or exposure to harsh conditions.

Temperature and Environmental Performance

TPU tubing maintains its structural integrity across a wide temperature range, typically from -40°C to 85°C, depending on the specific formulation. This temperature stability ensures reliable performance in various environmental conditions, from cold storage facilities to hot industrial settings. The material's resistance to UV radiation and weathering further enhances its suitability for outdoor applications.

Environmental considerations are increasingly important in material selection, and TPU tubing addresses these concerns effectively. Many TPU formulations are recyclable and can be manufactured without harmful plasticizers, making them an environmentally responsible choice for modern applications.

Industrial Applications and Advantages

Medical and Healthcare Uses

In the medical field, TPU tubing has revolutionized device design and patient care. Its biocompatibility and sterilization compatibility make it ideal for various medical applications, from IV lines to catheter systems. The material's clarity allows for visual monitoring of fluid flow, while its flexibility ensures patient comfort during extended use.

The ability to maintain dimensional stability under sterilization conditions and resist bacterial growth makes TPU tubing particularly valuable in medical environments. Its non-toxic nature and compliance with medical regulations have made it a preferred choice for healthcare manufacturers worldwide.

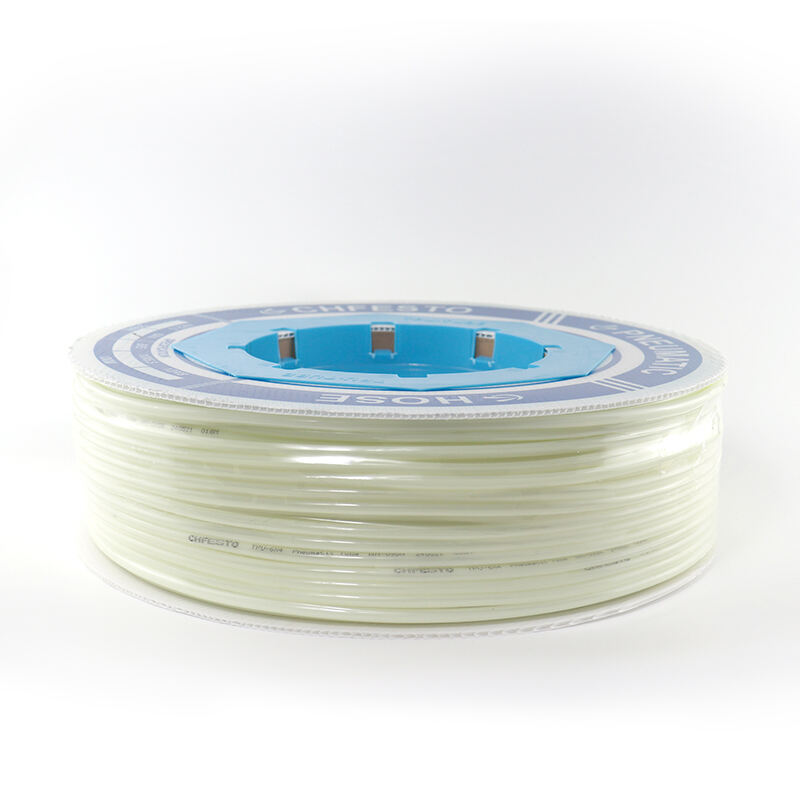

Manufacturing and Automation Applications

TPU tubing plays a crucial role in modern manufacturing processes, particularly in pneumatic systems and fluid transfer applications. Its excellent flexibility and kink resistance ensure reliable operation in complex machinery, while its durability reduces maintenance requirements and downtime. The material's ability to handle both pressure and vacuum conditions makes it versatile enough for various industrial processes.

In automation systems, TPU tubing's precise dimensional control and consistent performance characteristics contribute to improved system reliability. The material's resistance to vibration and ability to dampen noise also make it ideal for high-speed manufacturing environments.

Design Considerations and Selection Criteria

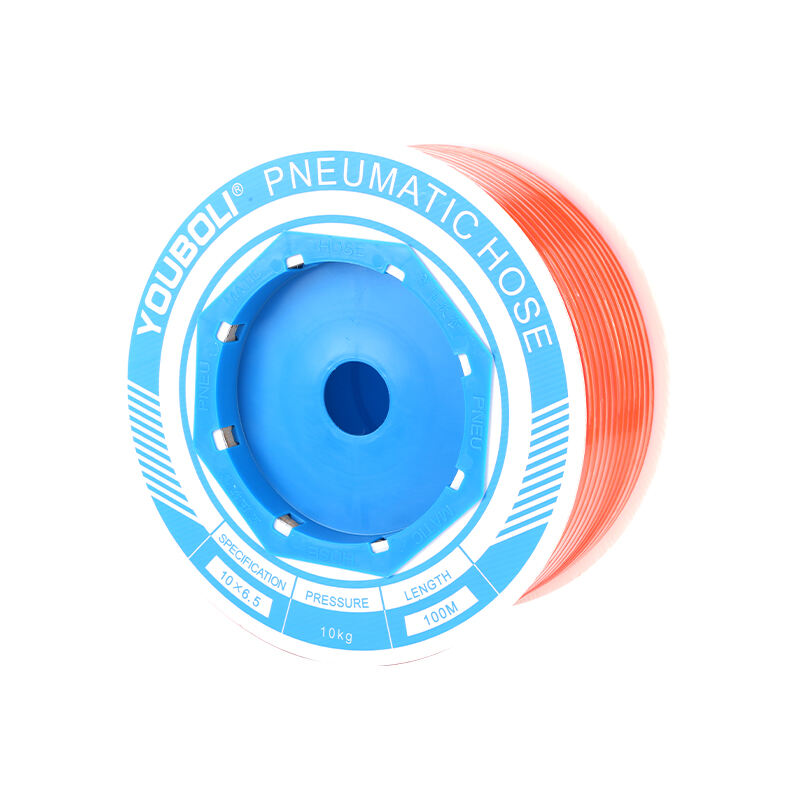

Size and Wall Thickness Options

Selecting the appropriate TPU tubing specifications requires careful consideration of several factors. Available in various sizes and wall thicknesses, TPU tubing can be customized to meet specific application requirements. The relationship between inner diameter, outer diameter, and wall thickness affects both flow characteristics and mechanical properties.

Engineers must consider factors such as pressure requirements, bend radius needs, and space constraints when selecting TPU tubing dimensions. The material's natural flexibility allows for smaller bend radii compared to other materials, offering greater design freedom in confined spaces.

Material Grade Selection

Different grades of TPU tubing are available to meet varying application demands. Food-grade variants ensure compliance with FDA regulations, while industrial grades offer enhanced chemical resistance or improved mechanical properties. The selection process should consider factors such as chemical exposure, temperature requirements, and regulatory compliance needs.

Manufacturers often provide detailed technical specifications and performance data to assist in selecting the most appropriate TPU tubing grade. This information includes mechanical properties, chemical resistance charts, and compliance certifications.

Installation and Maintenance Practices

Proper Installation Techniques

Successful implementation of TPU tubing systems begins with proper installation procedures. The material's flexibility requires appropriate support and routing to prevent stress concentration and ensure optimal performance. Proper fitting selection and installation techniques are crucial for maintaining system integrity and preventing leaks.

Installation considerations include minimum bend radius requirements, proper support spacing, and protection from potential physical damage. Following manufacturer guidelines for cutting, connecting, and securing TPU tubing helps ensure reliable long-term performance.

Maintenance and Monitoring

While TPU tubing is known for its low maintenance requirements, regular inspection and preventive maintenance can further extend its service life. Periodic visual inspections can identify potential issues before they affect system performance. The material's transparency facilitates easy monitoring of flow conditions and early detection of any contamination or wear.

Maintenance practices should include checking for proper alignment, inspecting fittings for security, and monitoring for any signs of degradation or damage. Proper cleaning procedures and chemical compatibility awareness help maintain the tubing's performance characteristics over time.

Frequently Asked Questions

What makes TPU tubing different from other types of tubing materials?

TPU tubing stands out due to its unique combination of flexibility, durability, and chemical resistance. Unlike traditional materials, it offers superior wear resistance, excellent clarity, and the ability to maintain its properties across a wide temperature range while remaining environmentally friendly and often recyclable.

How long can TPU tubing typically last in industrial applications?

The lifespan of TPU tubing varies depending on application conditions, but it generally offers excellent longevity due to its superior wear resistance and chemical stability. Under normal operating conditions, TPU tubing can last several years, with many installations exceeding 5-10 years of service life when properly maintained.

Can TPU tubing be used in food processing applications?

Yes, specific grades of TPU tubing are FDA-approved and suitable for food processing applications. These food-grade variants meet strict regulatory requirements for food contact materials while maintaining the material's beneficial properties of flexibility, durability, and ease of cleaning.