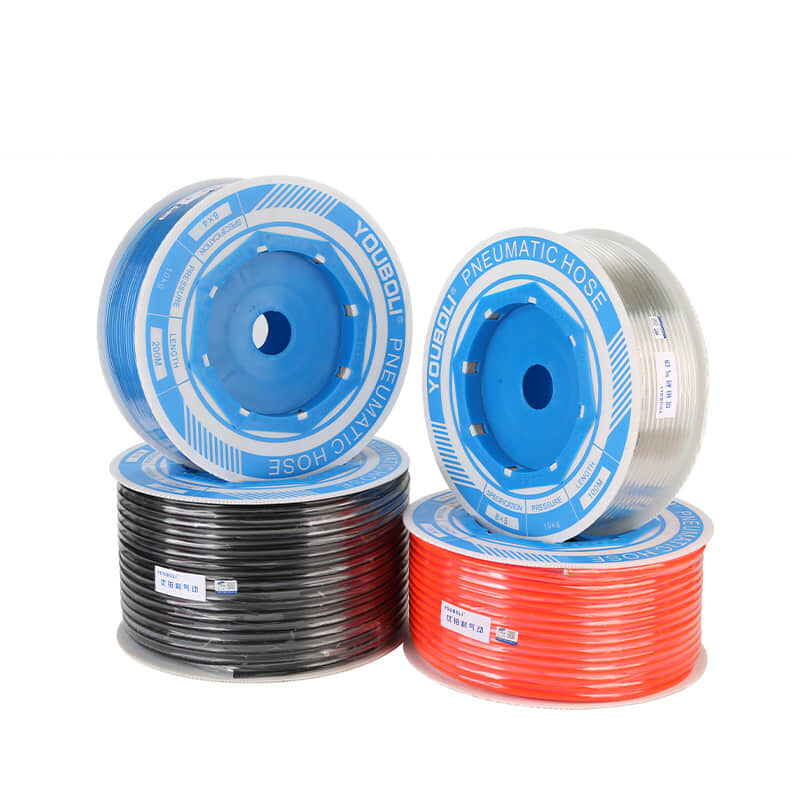

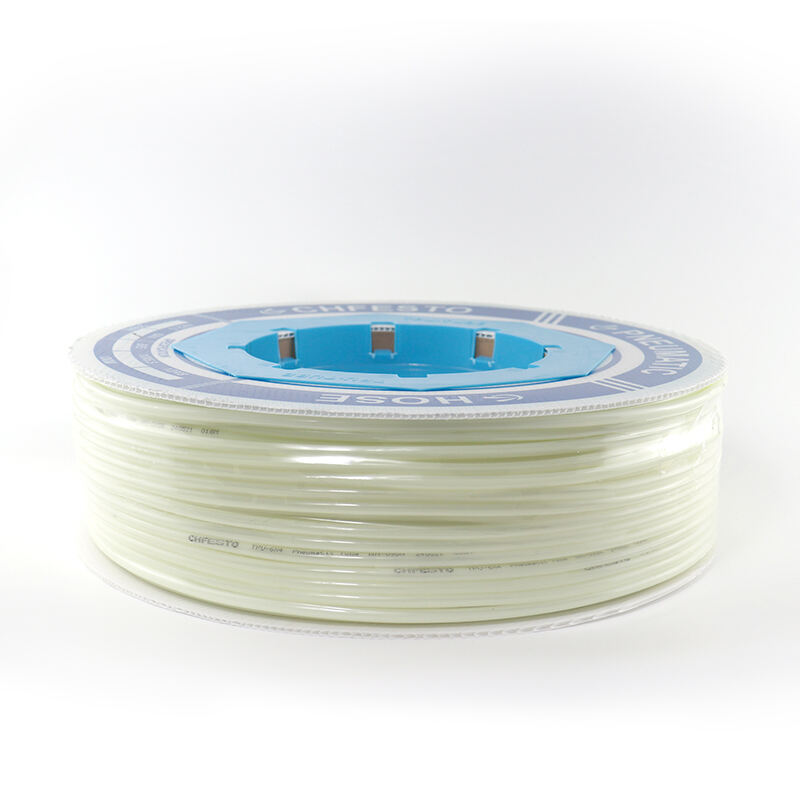

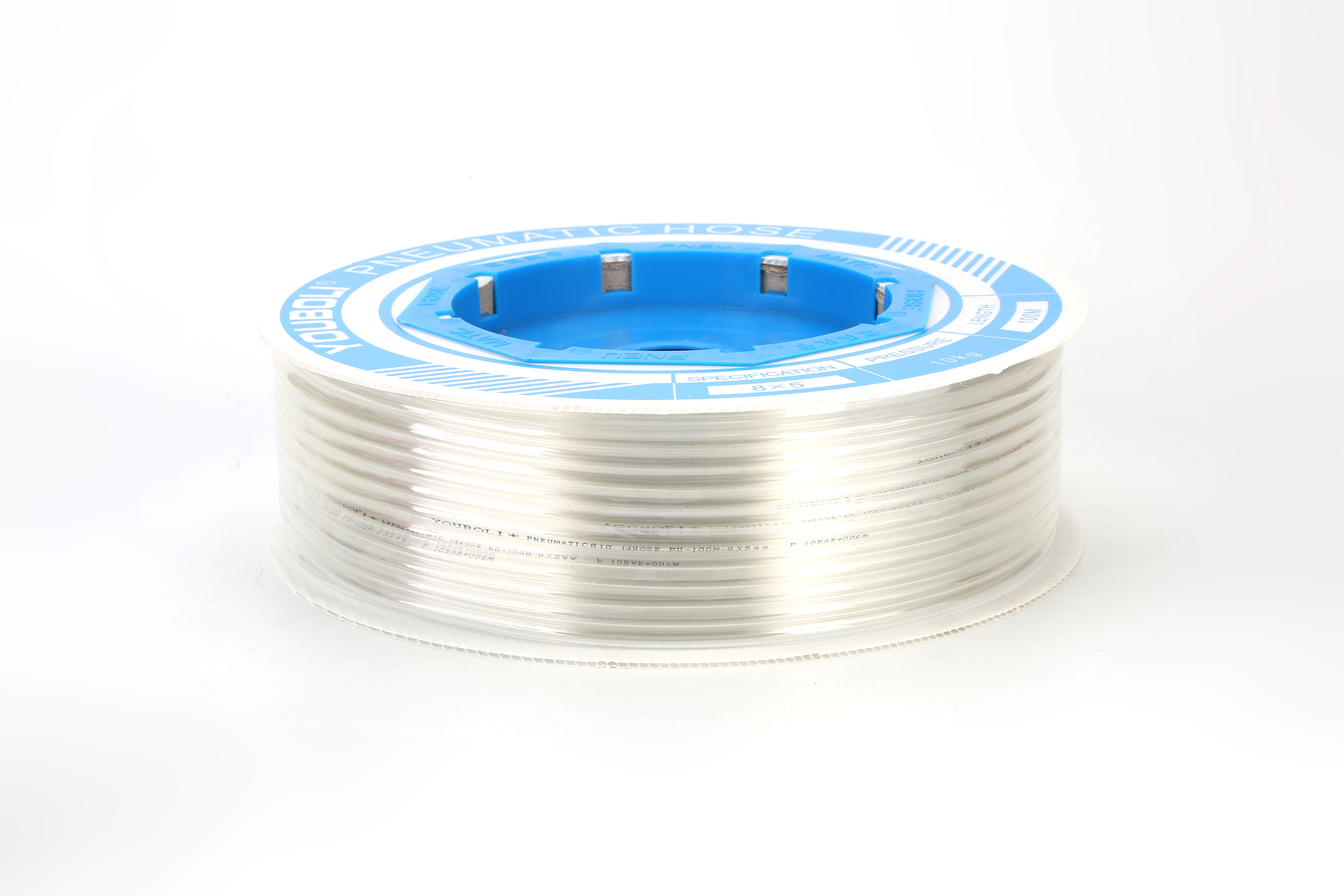

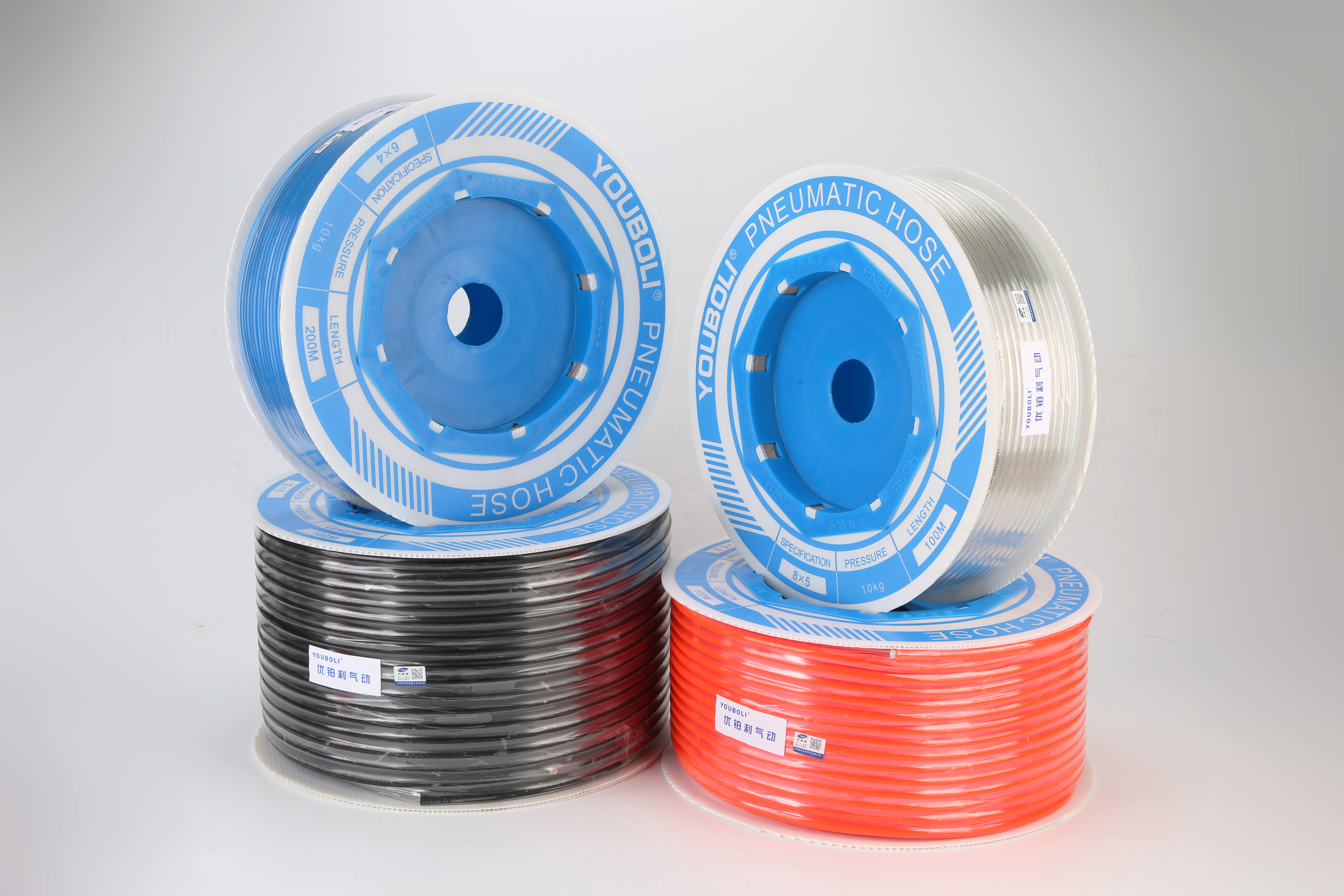

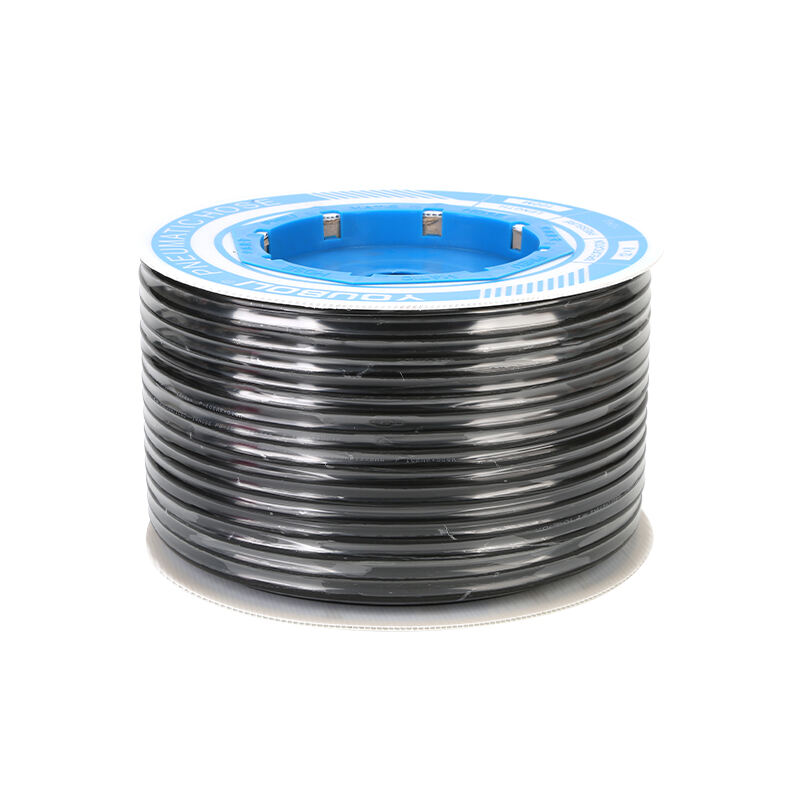

air compressor hose parts

Air compressor hose parts are essential components that ensure the efficient and reliable operation of compressed air systems. These parts include connectors, couplings, fittings, adapters, and quick-release mechanisms that work together to create a seamless air delivery system. The primary function of these components is to maintain airtight connections while facilitating the smooth flow of compressed air from the compressor to various tools and equipment. Modern air compressor hose parts are engineered with high-grade materials such as brass, steel, and durable synthetic compounds, offering excellent resistance to wear, corrosion, and pressure fluctuations. The design of these parts incorporates precision threading and specialized sealing mechanisms to prevent air leaks and maintain consistent pressure levels. These components are versatile enough to accommodate different hose sizes and types, making them suitable for various applications across industrial, commercial, and residential settings. The technological features include quick-connect systems, swivel joints for enhanced mobility, and pressure-relief mechanisms for safety. These parts are designed to meet industry standards and safety requirements, ensuring reliable performance under varying operating conditions.