pneumatic push fittings

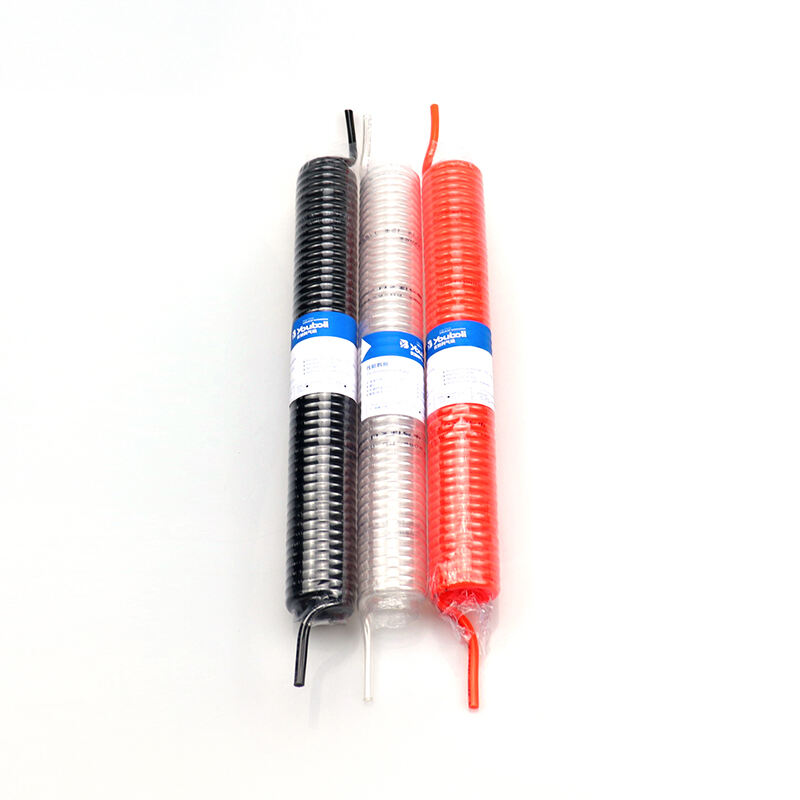

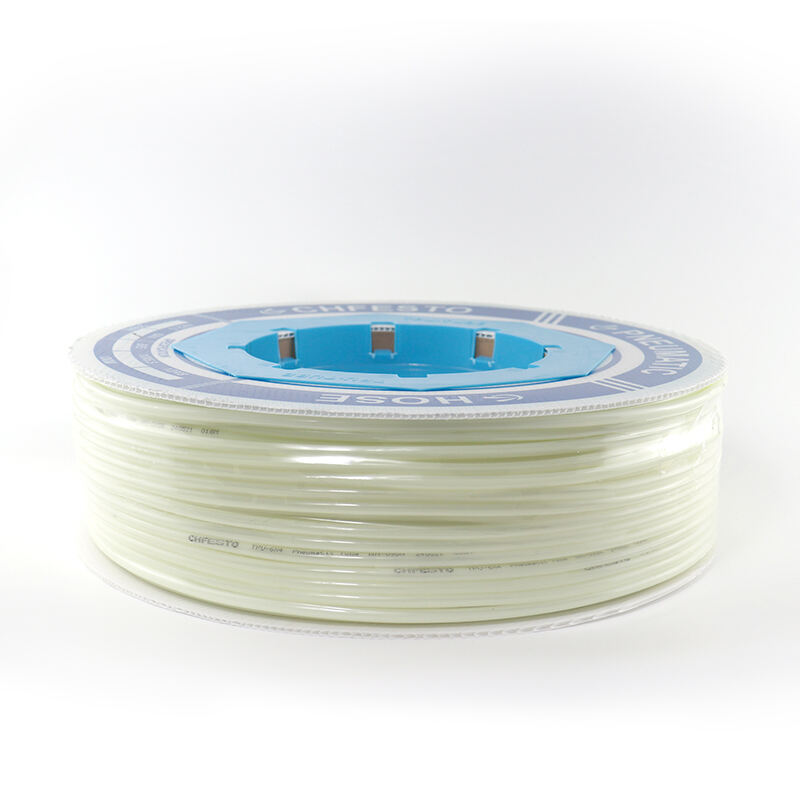

Pneumatic push fittings represent a crucial advancement in fluid and air connection technology, offering a reliable and efficient solution for various industrial applications. These innovative components are designed to create secure, leak-free connections between tubes and pipes without the need for specialized tools or complex installation procedures. The fittings utilize a unique collet mechanism that automatically grips the tube when inserted, while an internal O-ring provides an airtight seal. This dual-action system ensures both mechanical grip and pneumatic sealing, making them ideal for compressed air systems, pneumatic control circuits, and fluid transfer applications. The fittings are manufactured using high-grade materials, typically including nickel-plated brass bodies, stainless steel collets, and durable elastomer seals, ensuring long-term reliability and corrosion resistance. Their design accommodates various tube sizes and materials, including nylon, polyurethane, and other polymeric tubes commonly used in pneumatic systems. The push-to-connect mechanism significantly reduces installation time while maintaining consistent connection quality across multiple fitting points. These fittings also feature built-in tube release mechanisms, allowing for quick system modifications or maintenance without damaging the components.