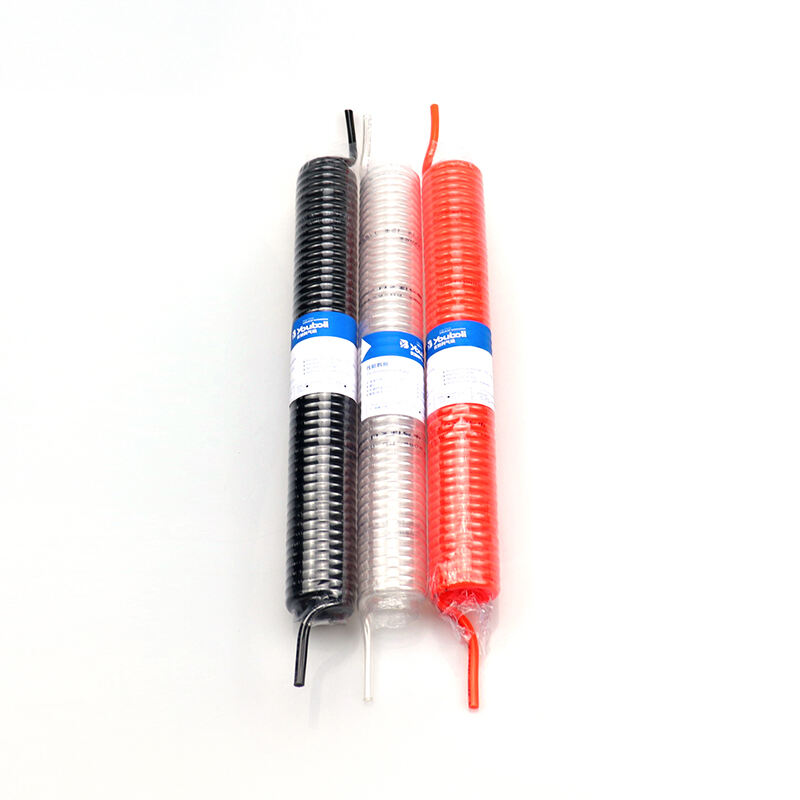

pneumatic connectors fittings

Pneumatic connectors fittings are essential components in pneumatic systems, serving as crucial links that enable the efficient transfer of compressed air between various system elements. These precision-engineered components are designed to ensure secure, leak-free connections while maintaining optimal system pressure and flow characteristics. Modern pneumatic connectors incorporate advanced sealing technologies and materials, including high-grade brass, stainless steel, or engineered polymers, making them suitable for diverse industrial applications. They come in various configurations, such as push-to-connect, quick-disconnect, and threaded fittings, each designed to meet specific operational requirements. These fittings are engineered to withstand high pressure conditions while providing reliable performance in demanding industrial environments. The design typically includes features like double O-ring seals, positive tube locking mechanisms, and corrosion-resistant materials that ensure long-term reliability and safety. Their applications span across multiple industries, from manufacturing and automation to food processing and medical equipment, where precise air distribution and control are paramount.