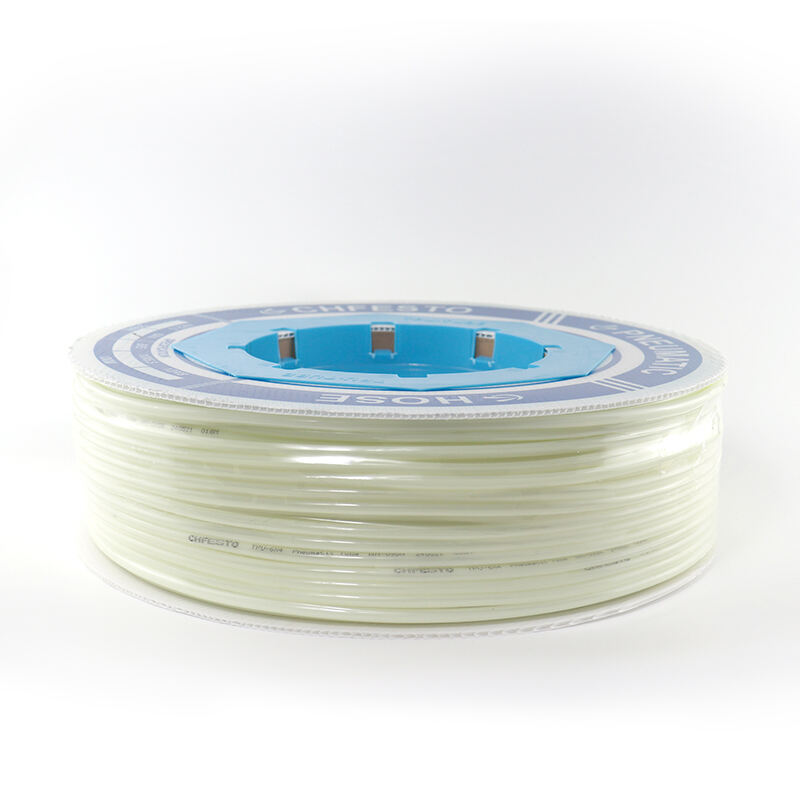

hose air duct

A hose air duct is a flexible ventilation system component designed to efficiently transport air, gases, and light materials through various industrial and commercial settings. These essential components are engineered with high-grade materials, typically featuring a reinforced construction that combines durability with flexibility. The primary function of a hose air duct is to provide a reliable pathway for air distribution, temperature control, and ventilation in both industrial processes and HVAC systems. The design incorporates spiral wire reinforcement within flexible fabric or synthetic materials, allowing for optimal airflow while maintaining structural integrity. These ducts can be customized in different diameters, lengths, and materials to suit specific applications, from dust collection in woodworking shops to ventilation in manufacturing facilities. Modern hose air ducts often feature temperature-resistant properties, making them suitable for both heated and cooled air transport. They are engineered to minimize pressure drops and maintain consistent airflow, ensuring efficient operation in various environmental conditions. The versatility of hose air ducts makes them indispensable in applications ranging from industrial exhaust systems to portable air conditioning units.