air compressor discharge hose

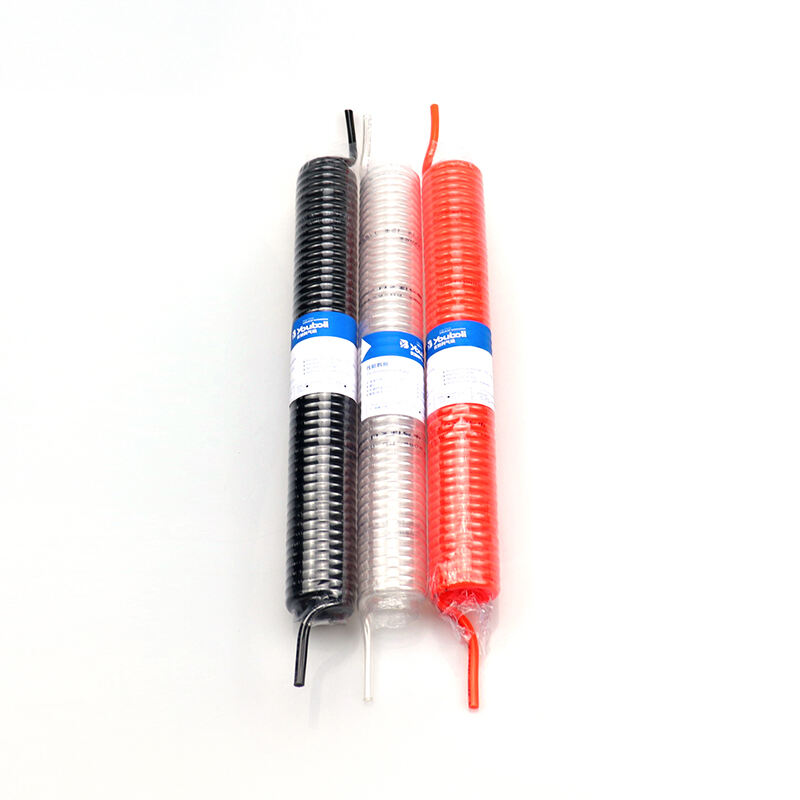

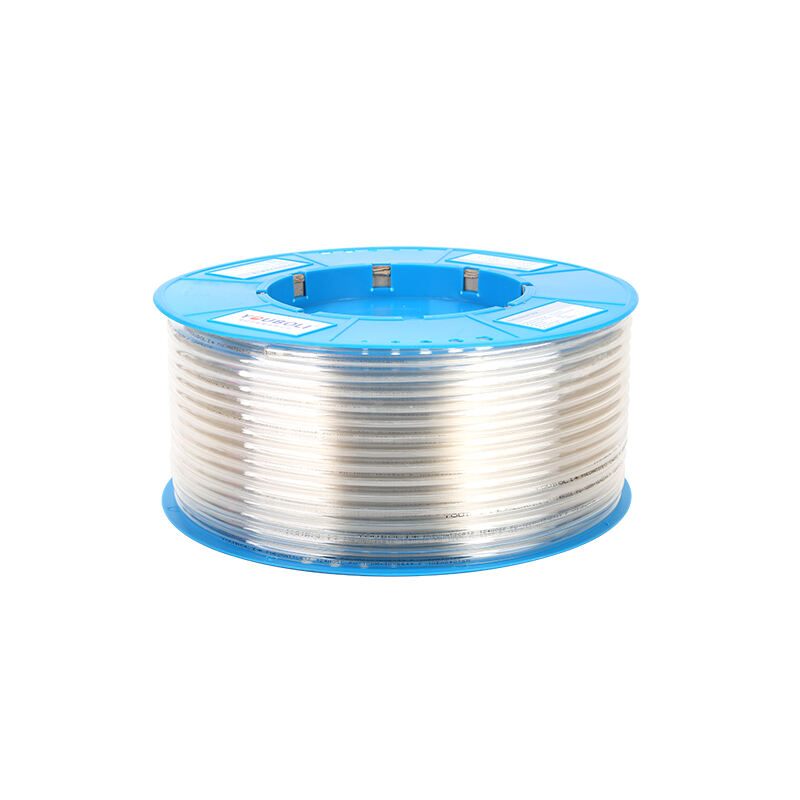

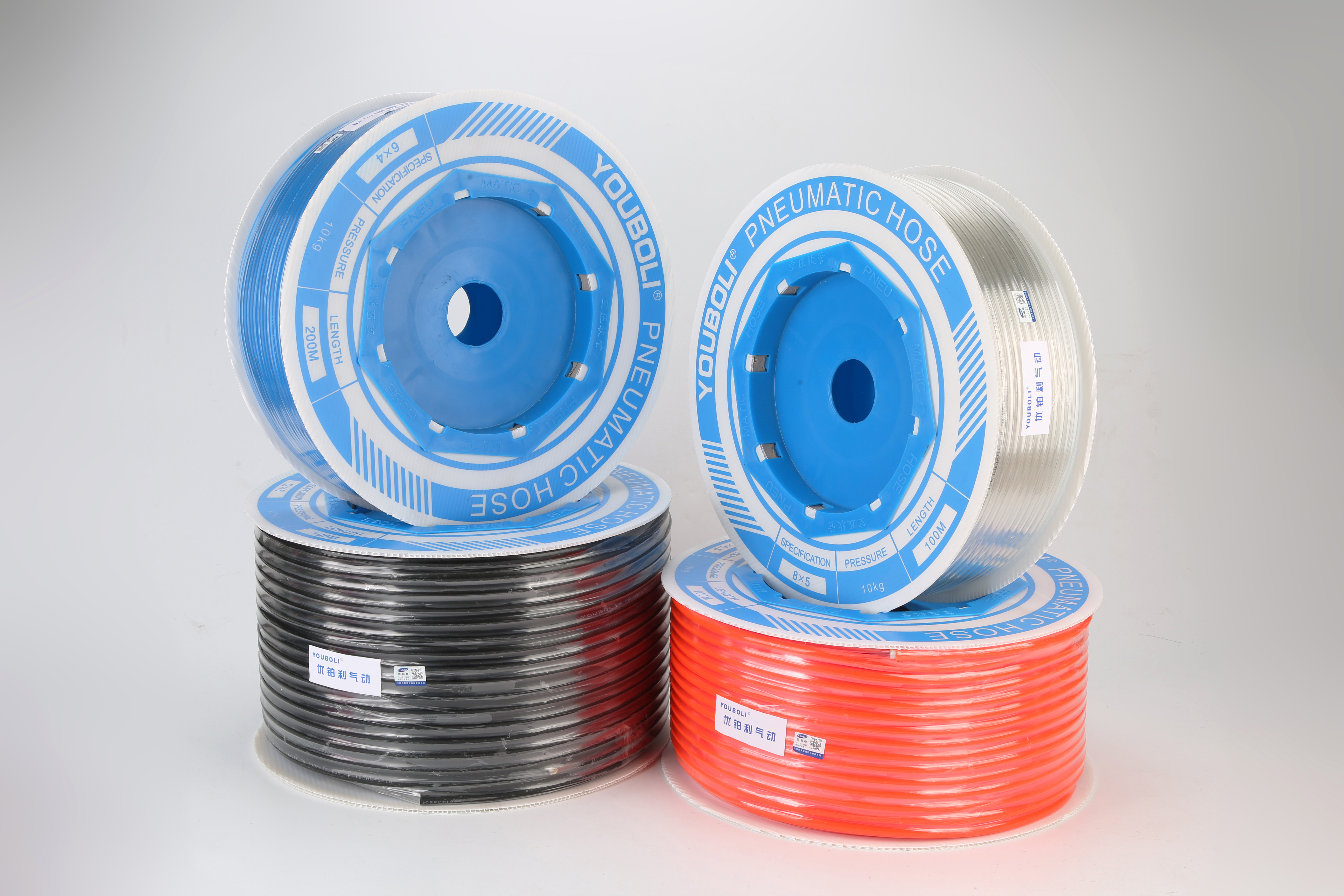

An air compressor discharge hose serves as a crucial component in pneumatic systems, designed to safely channel compressed air from the compressor to various tools and equipment. This specialized hose is engineered with reinforced materials, typically featuring multiple layers including an inner tube, reinforcement layers, and an outer cover to withstand high pressures and ensure safe operation. The inner layer is crafted from materials resistant to oil and heat, while the outer layer provides protection against environmental factors, abrasion, and wear. These hoses are available in various diameters and lengths to accommodate different flow requirements and applications. They are specifically designed to handle the high temperatures generated during air compression while maintaining flexibility for ease of use. The construction includes brass or steel fittings at both ends, ensuring secure connections and preventing air leaks. Modern air compressor discharge hoses incorporate advanced materials that offer superior durability while remaining lightweight, making them easier to maneuver in various working environments. These hoses are essential in industrial settings, construction sites, automotive shops, and manufacturing facilities where compressed air is a primary power source for tools and equipment.