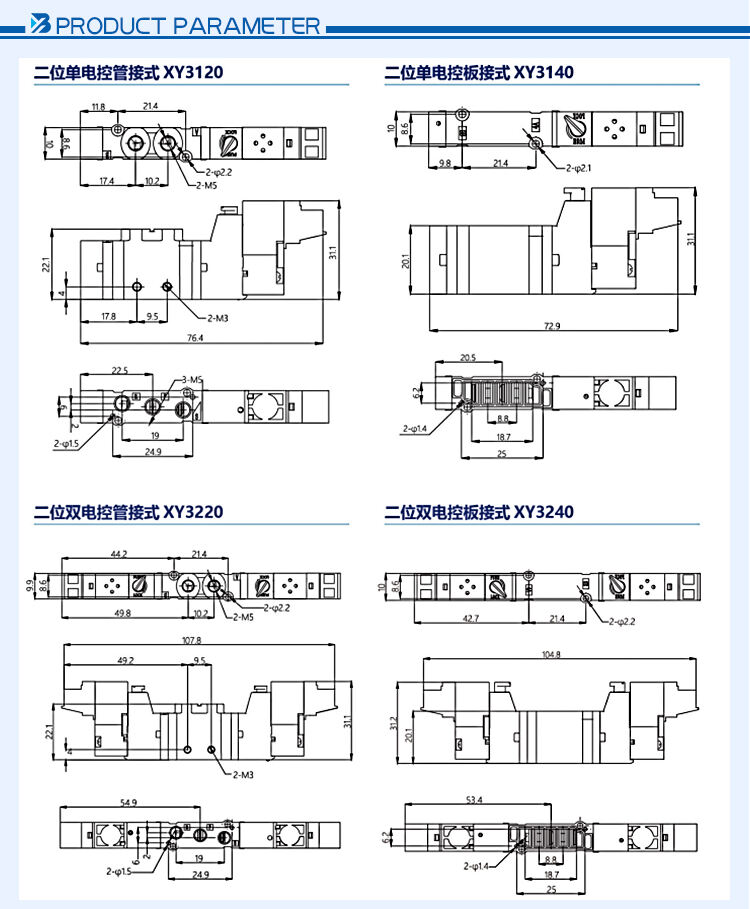

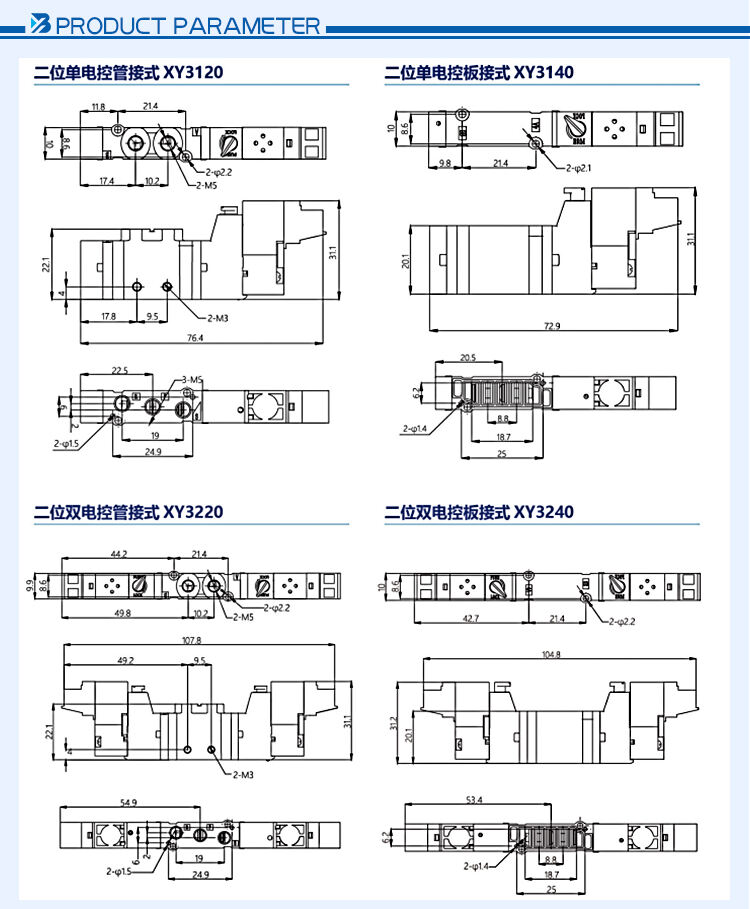

Structural Design

Mostly adopt a compact design. For example, the width of some models is only 10mm or 15mm, which takes up little space and is convenient for installation. The valve body can be installed in a body port type or an integrated block type, with flexible installation methods, suitable for the layout requirements of different devices. The stroke of the spool in some solenoid valves is extremely small, which can reduce component wear and extend the service life.

Sealing Performance

Special sealing materials are used. For example, some products are sealed with high-performance PTFE Glyd ring, which has a good sealing effect. It can effectively prevent gas or liquid leakage, ensure the stable operation of the equipment, and at the same time extend the service life of the valve itself.

Working Performance

-

Wide Applicable Pressure Range: The common working pressure range is 2 - 10bar, and the specific pressure ranges vary for different models, which can meet the usage requirements of multiple pressure conditions.

-

High Action Frequency: The maximum action frequency of some 2-position single-electrical controlled and double-electrical controlled 5/2 solenoid valves can reach 10Hz, which means that multiple action switches can be achieved within a unit of time. They have a rapid response and are suitable for automated control scenarios with high requirements for control response speed.

-

Fast Speed: The maximum speed of some models can reach 1000 cycles per minute, which can quickly switch the on and off of the gas or liquid circuit, improving the operating efficiency of the equipment.

Electrical Characteristics

Mostly use DC power supply, such as DC12V and DC24V, which can adapt to common industrial power supplies. Some are equipped with a power-saving circuit, with a starting power of 1.8W and a maintaining power of 0.5W, showing obvious energy-saving effects. The allowable voltage can fluctuate within ±10% of the rated voltage, with relatively low requirements for voltage stability, making it more stable to use. An over-current protection circuit can also be optionally configured to prevent the solenoid valve from being damaged due to abnormal current. Some products are equipped with LED indicators for easy observation of the working state.

Maintenance

Some products do not require additional lubrication, reducing maintenance steps and costs, and making maintenance more convenient.