I. Core Functional Characteristics

High-pressure Airflow Cleaning

Using compressed air to generate a strong airflow, it can quickly blow away dust, debris, fibers, and other impurities from the surface and gaps of equipment, featuring high cleaning efficiency.

The airflow intensity is adjustable (for some models) to adapt to different scenarios: for example, low air pressure is required for precision electronic components to avoid damage, while high air pressure can be used for industrial equipment to remove stubborn dust accumulation.

Directional Concentrated Blowing

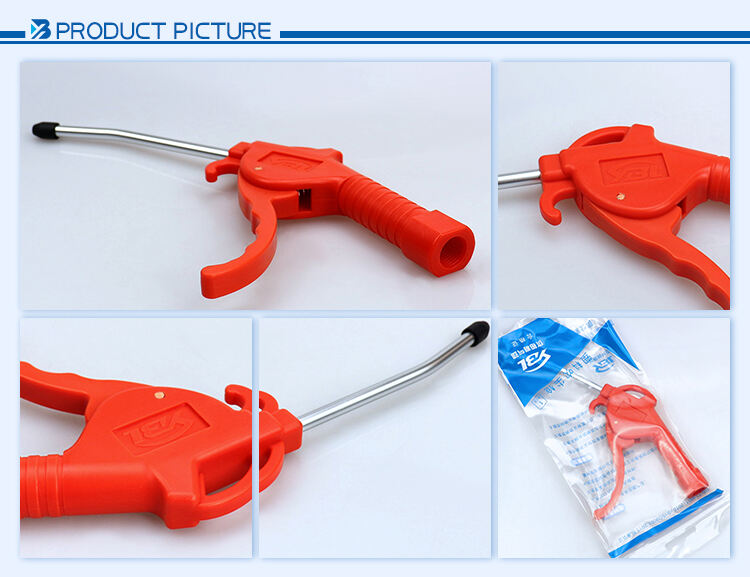

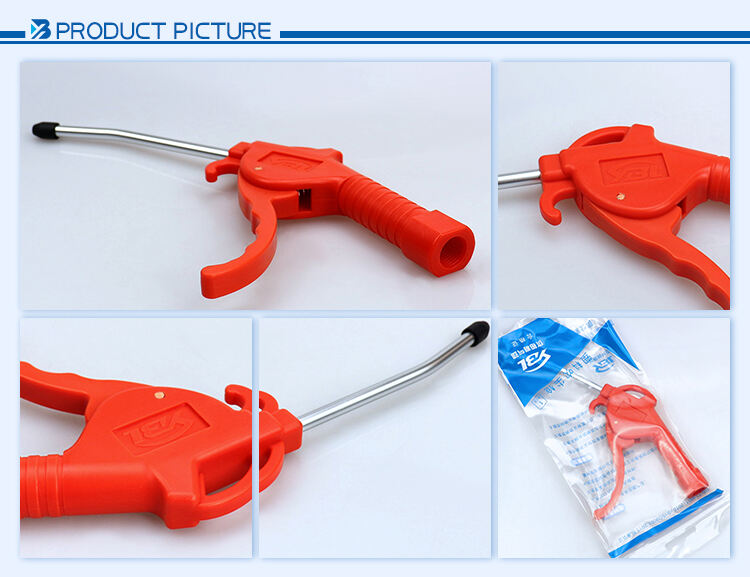

The muzzle is usually designed with a slender nozzle or replaceable nozzles of different shapes (such as straight heads, elbow heads, flat nozzles, etc.), making it easy to accurately aim at hard-to-clean areas like narrow gaps and corners (e.g., gaps between keyboard keys, grooves in mechanical parts).

II. Structural and Design Features

Portable and Flexible

Most dust blower guns use lightweight materials (such as engineering plastics, aluminum alloys), and the handle is designed ergonomically for comfortable grip, suitable for long-term use.

Some models are handheld and can be used by connecting an air pipe; there are also small portable air tank models (no external air source needed), suitable for outdoor or air-source-free scenarios.

Safety Protection Design

Some products are equipped with an air pressure regulator to prevent excessive air pressure from damaging items; the muzzle may be equipped with a protective net to avoid foreign objects from spraying out or the airflow directly impacting the human body.

Insulating materials (such as plastic gun bodies) are suitable for cleaning live equipment, reducing the risk of electric shock.