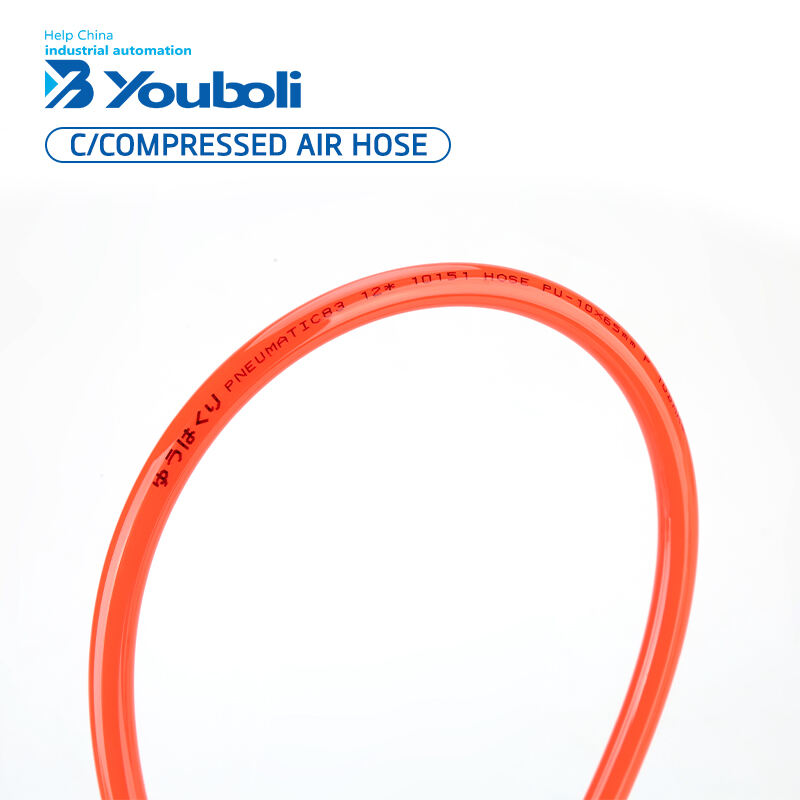

air pressure hose

An air pressure hose is a vital component in pneumatic systems, engineered to safely transport compressed air from compressors to various tools and equipment. These specialized hoses are constructed with multiple layers of durable materials, typically including an inner tube, reinforcement layers, and an outer cover, designed to withstand high pressure levels and ensure consistent air delivery. The inner tube is specifically engineered to maintain air quality and prevent leakage, while the reinforcement layers, often made of high-tensile steel wire or synthetic fiber, provide the necessary strength to contain pressurized air. The outer cover protects against environmental factors, abrasion, and chemical exposure. Modern air pressure hoses incorporate advanced features such as kink resistance, temperature tolerance, and flexible handling characteristics, making them suitable for diverse industrial applications. These hoses are available in various sizes, pressure ratings, and material compositions to accommodate different operational requirements, from light-duty workshop tasks to heavy industrial processes. The design emphasizes safety features including burst resistance and secure coupling connections, ensuring reliable performance in demanding conditions.