air compressor whip hose

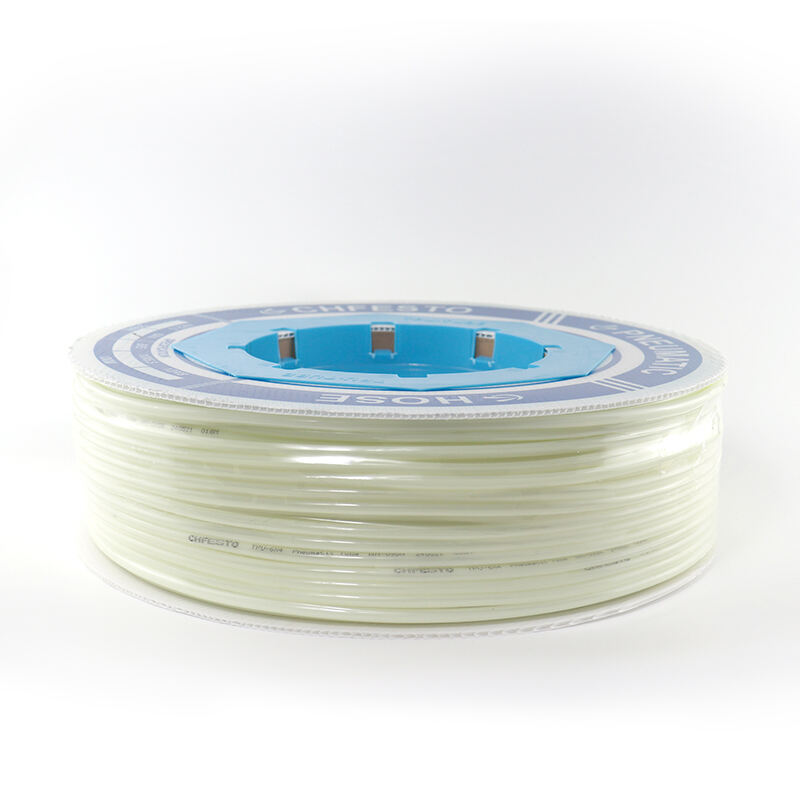

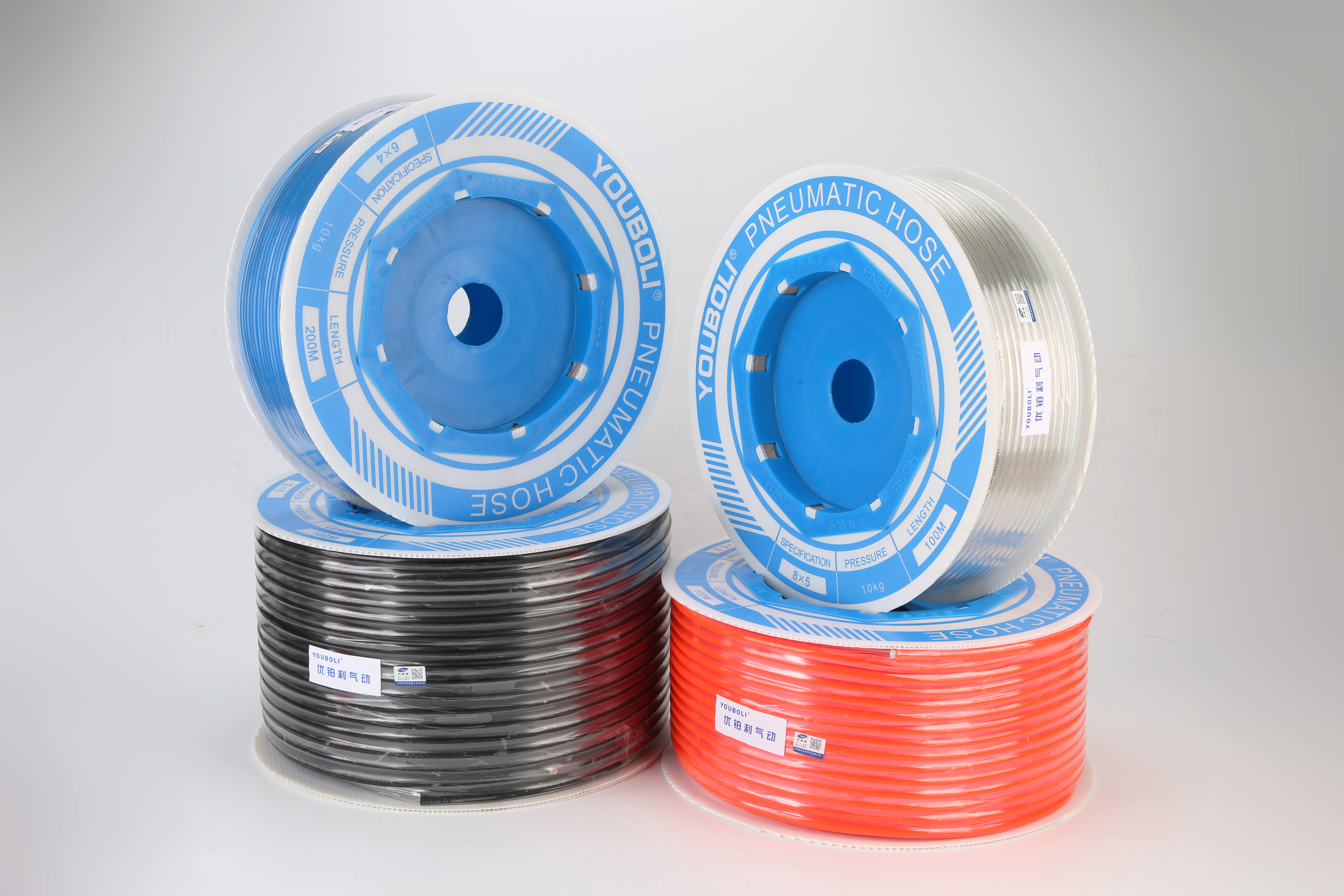

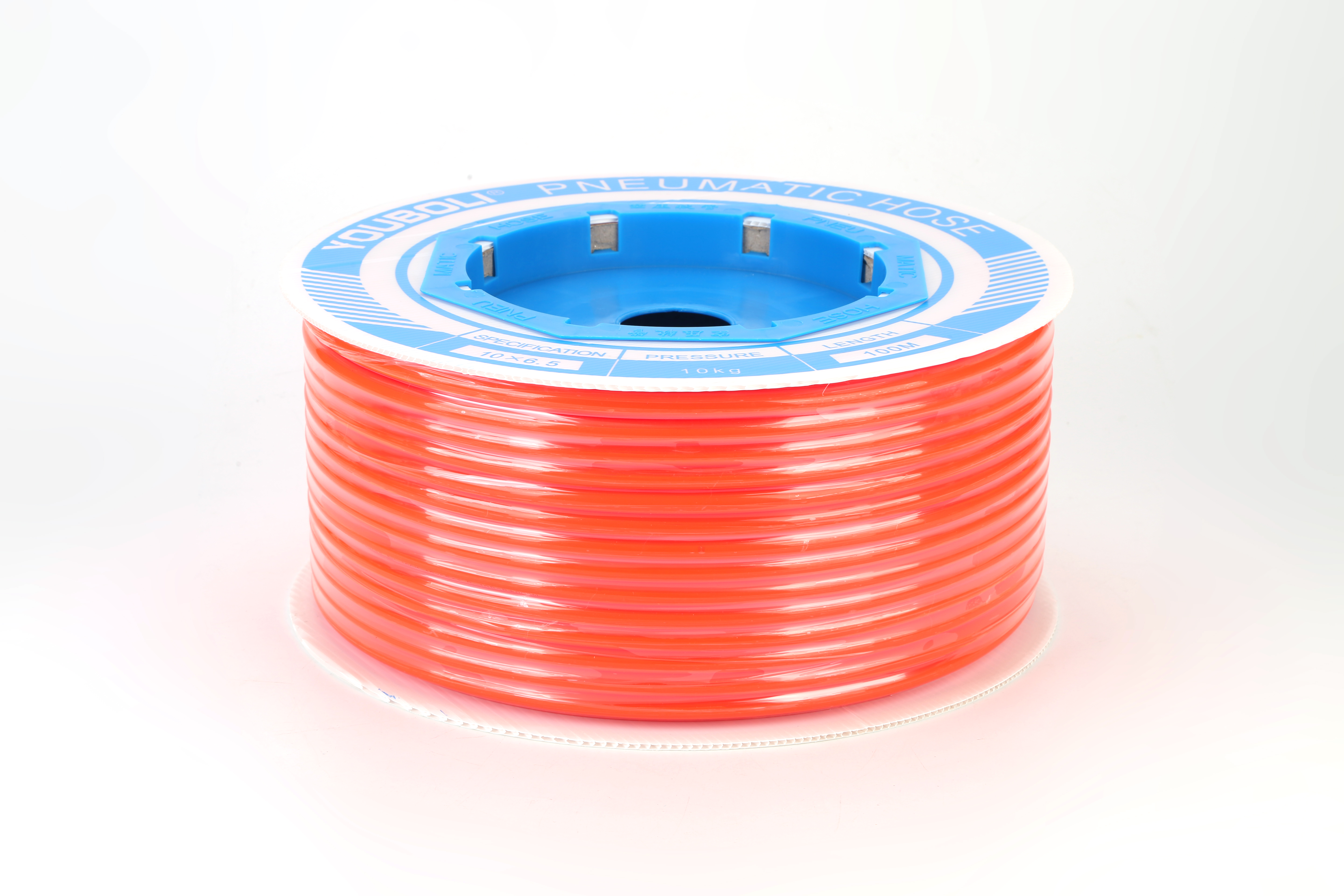

An air compressor whip hose is a specialized, flexible connector designed to bridge the gap between stationary air compressors and pneumatic tools or equipment. This essential component features a highly durable construction, typically made from reinforced rubber or synthetic materials capable of withstanding high pressure and frequent movement. The whip hose serves as a crucial safety element by absorbing vibrations and reducing the transfer of movement between the tool and the main air line, effectively preventing damage to both the equipment and the primary air system. These hoses are engineered with specific pressure ratings, usually ranging from 200 to 300 PSI, and come in various lengths to accommodate different working environments. The distinctive feature of a whip hose is its flexibility and ability to maintain its structural integrity even under constant movement and stress. Modern whip hoses incorporate advanced materials that resist kinking, weather damage, and oil contamination, ensuring consistent air flow and pressure maintenance throughout operation. The design typically includes high-quality fittings on both ends, usually featuring quick-connect couplers for easy attachment and detachment, making them ideal for professional workshops and industrial applications.