3 4 quick connect air hose fittings

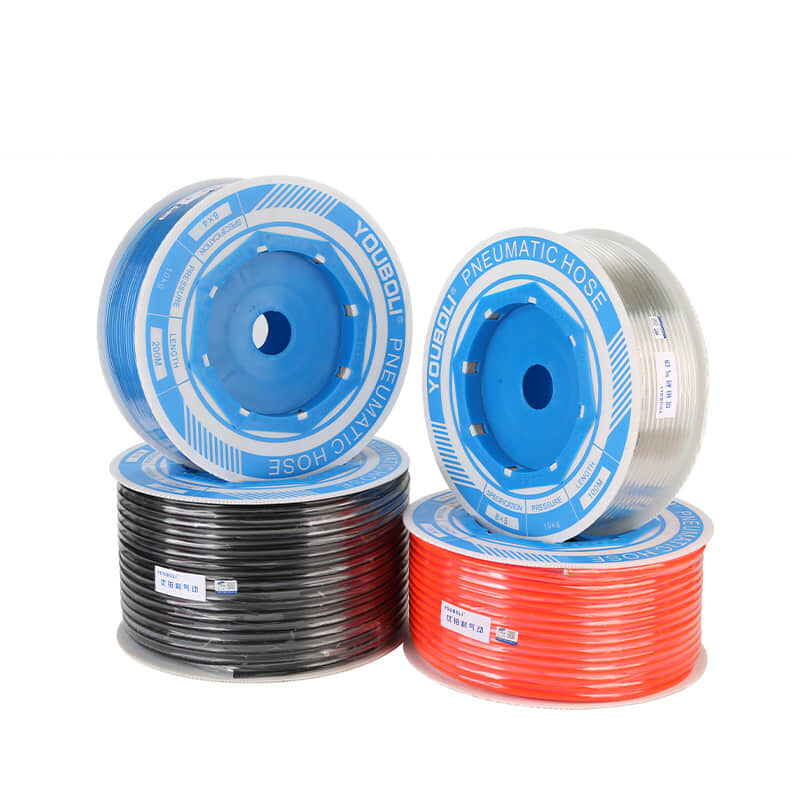

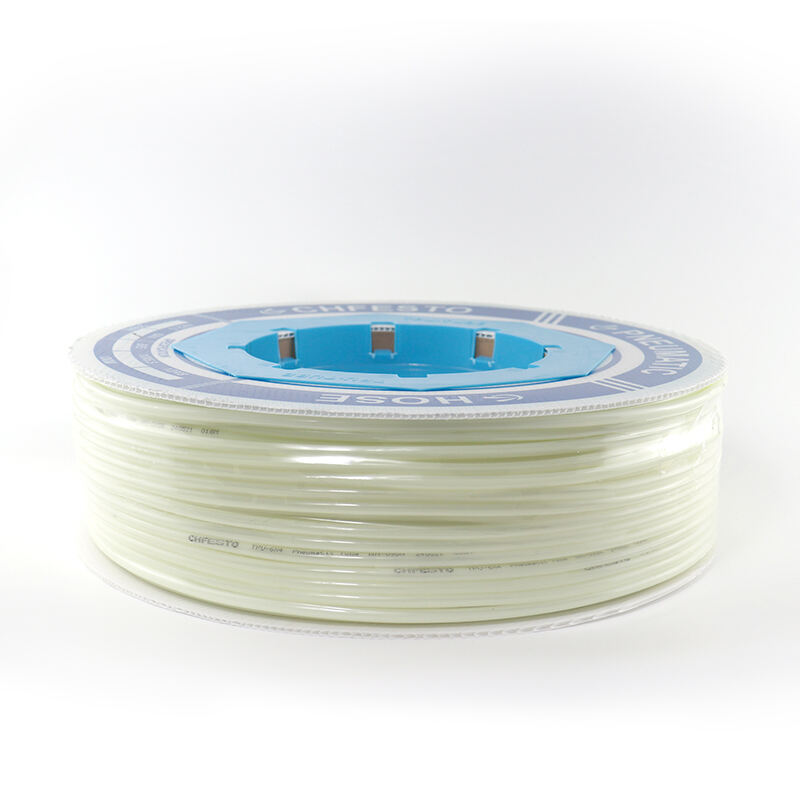

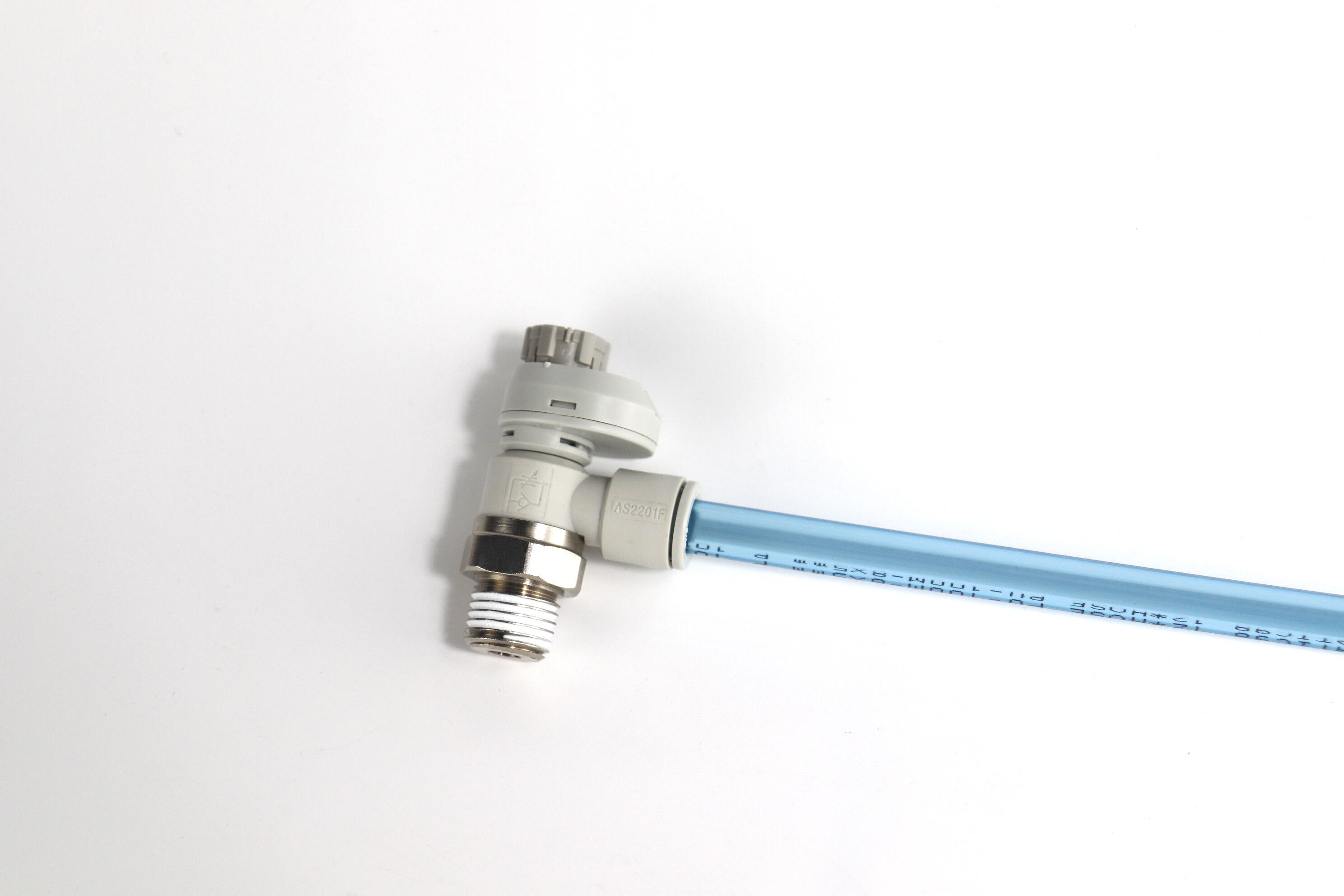

The 3/4 quick connect air hose fittings represent a crucial advancement in pneumatic system connections, offering seamless and efficient coupling solutions for industrial and professional applications. These fittings are engineered with precision to provide secure, leak-free connections while allowing for rapid attachment and detachment of air hoses. Constructed from durable materials such as brass, steel, or high-grade aluminum, these fittings typically feature a spring-loaded mechanism that ensures a positive seal when connected. The 3/4-inch size makes them ideal for high-flow applications where larger air volume is required, such as industrial compressors, pneumatic tools, and heavy machinery operations. The design incorporates automatic shut-off valves that prevent air loss when disconnecting, maintaining system pressure and ensuring workplace safety. These fittings are compatible with standard 3/4-inch air hoses and typically operate at pressures up to 300 PSI, depending on the specific model and manufacturer specifications.