Quick Links

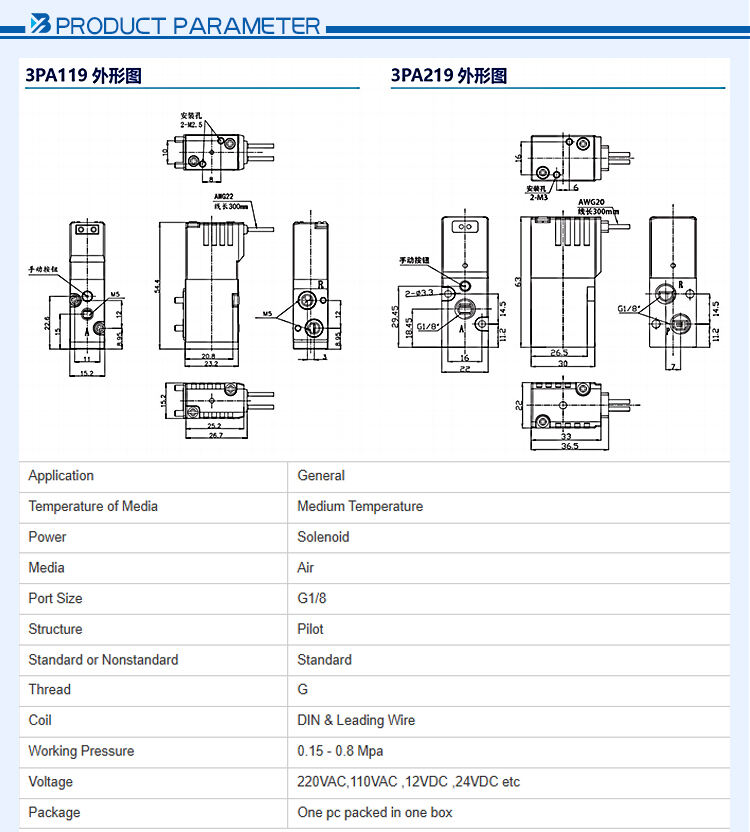

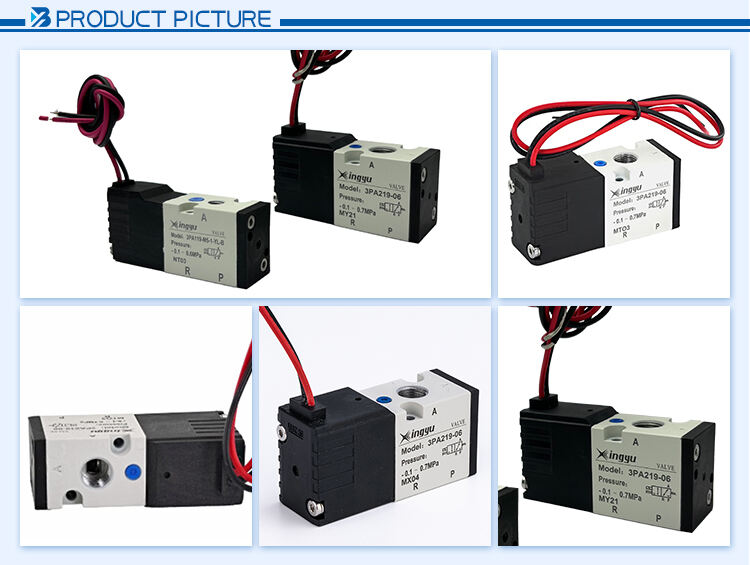

High Quality 3PA219 Two-Position Three-Way Vacuum Solenoid Valve Low Power Direct-Acting High Frequency Commutation Replacement

Copyright © 2026 Youboli Pneumatic Technology Co., Ltd. All right reserved - Privacy policy