YOUBOLI FRC 1.6MPa Pneumatic Parts Air Source Oil-Water Separator Pressure Regulating Valve Spray Paint for Industrial Construction

In terms of the filtration function:

High-efficiency impurity filtration: It can effectively remove solid impurities such as dust, rust, and oil droplets, as well as liquid pollutants in the compressed air, providing a clean air source for downstream equipment and protecting the equipment from wear and damage. For example, for precision pneumatic instruments, it can prevent impurities from entering, which may lead to measurement errors or malfunctions.

Diverse filtration accuracies: Generally, a variety of filtration accuracies are provided for selection, such as 25μm, 5μm, or even higher accuracies, which can meet the requirements for air quality in different application scenarios. For instance, in industries with high requirements for air quality, such as food processing and electronics manufacturing, a high-precision filtration level can be selected.

Long-life filter elements: The filter elements are made of high-quality materials, featuring good corrosion resistance and anti-clogging ability. With a long service life, they reduce the frequency of filter element replacement and maintenance costs.

In terms of the pressure reduction function:

Precise pressure adjustment: It can accurately adjust the input high-pressure air to the required stable pressure output. The pressure adjustment range is usually wide, enabling it to adapt to the working pressure requirements of different devices. For example, some devices require a low and stable air pressure, and the LFR series can precisely control the pressure within an appropriate range.

Good pressure stability: Even when there are fluctuations in the air source pressure or changes in flow rate, it can still maintain the stability of the output pressure, ensuring the normal operation of the equipment. Even during peak periods of air consumption in the factory, it can provide a stable air pressure for the equipment.

Low pressure loss: During the process of achieving the pressure reduction function, it tries to minimize the loss of air pressure, improve energy utilization efficiency, and reduce operating costs.

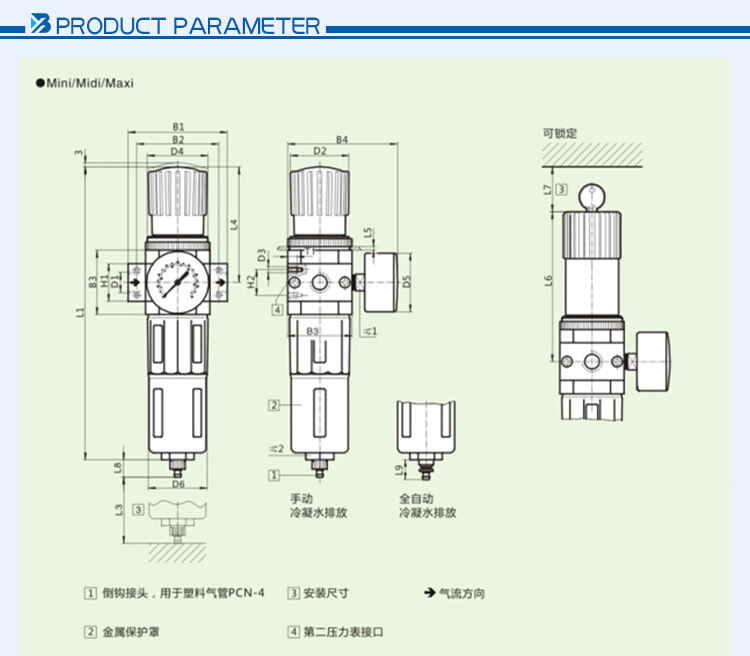

In terms of structure and design:

Compact design: The overall structure is compact, with a small volume, light weight, and occupying less space. It is convenient to install in various devices and systems, especially suitable for situations with limited space.

Flexible installation methods: It supports various installation methods, such as wall-mounted and pipeline-mounted. You can choose according to the actual installation environment and requirements, which is convenient and quick.

Visual design: Some products are equipped with transparent visual windows or pressure gauges, which facilitate operators to intuitively observe parameters such as the accumulated water inside the filter and the pressure value, and carry out maintenance and adjustment in a timely manner.

In terms of durability and reliability:

Manufactured with high-quality materials: The housing and key components are made of high-strength and corrosion-resistant materials, such as aluminum alloy and stainless steel, which can adapt to harsh industrial environments and ensure the long-term stable operation of the product.

Strong anti-interference ability: It has good anti-vibration and anti-impact performance. In complex industrial production environments, it can effectively resist external interference and ensure the reliability of its performance.

High safety performance: It is equipped with an overpressure protection device. When the output pressure exceeds the set value, it can automatically take protective measures to prevent the equipment from being damaged due to overpressure and ensure production safety.

Type |

Micro |

Mini |

Midi |

Maxi |

||||||||||||

Air Coupling |

M5 |

M7 |

G1/8 |

QS4 |

QS6 |

G1/8 |

G1/4 |

G3/8 |

G1/4 |

G3/8 |

G1/2 |

G3/4 |

G1/2 |

G3/4 |

G1 |

|

Working Medium |

Compressed Air |

|||||||||||||||

Structural Features |

Filter Pressure Reducing Valve With/Without Pressure Gauge |

|||||||||||||||

Way To Install |

Through The Attachment |

|||||||||||||||

|

Tubular Mounting |

|||||||||||||||

Installation Site |

Vertical ±5° |

|||||||||||||||

Pressure Reducing Valve Lock |

Rotate Handle With Lock |

|||||||||||||||

|

|

Swivel Handle With IntegraTed Lock |

||||||||||||||

Filtration Grade(μm) |

5 |

5(or)40 |

||||||||||||||

Maximum Hysteresis(bar) |

0.3 |

0.2 |

0.4 |

|||||||||||||

Pressure Regulation Range(bar) |

0.5…7 |

0.5…7 |

||||||||||||||

|

|

0.5…12 |

||||||||||||||

Pressure Display |

Through Pressure Gauge |

|||||||||||||||

|

M5Preset |

G1/8Preset |

G1/4Preset |

G1/4Preset |

||||||||||||

Maximum Condensate Volume(cm³) |

3 |

22 |

43 |

80 |

||||||||||||

Inlet Pressure(bar) |

|

|||||||||||||||

|

Condensate Discharge |

manual operation |

1….10 |

2...16 |

|||||||||||||

|

semi-automatic |

1..10 |

|

|||||||||||||

|

full-automatic |

|

2.12 |

|||||||||||||

Copyright © 2026 Youboli Pneumatic Technology Co., Ltd. All right reserved - Privacy policy