YOUBOLI China Direct Wholesale GFC Series Pneumatic Parts-New Air Source Processor Dual-Unit Oil-Water Separator GCFC200/300 Filter

Type |

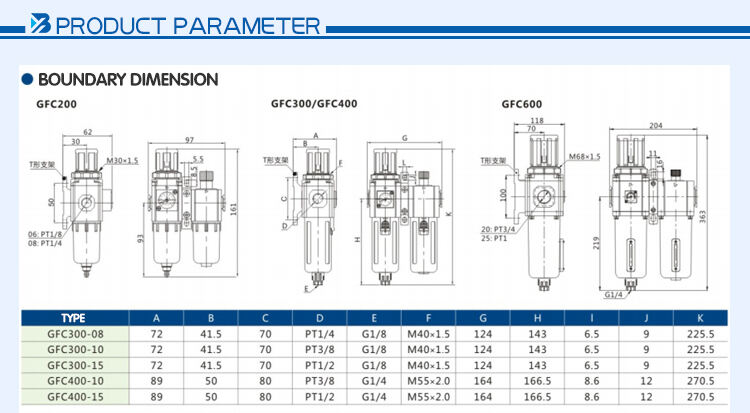

GFC200-06 |

GFC200-08 |

GFC300-08 |

GFC300-10 |

GFC300-15 |

GFC400-10 |

GFC400-15 |

GFC600-20 |

GFC600-25 |

|||||||||

Working Medium |

Air |

|||||||||||||||||

Joint Diameter |

PT1/8 |

PT1/4 |

PT1/4 |

PT3/8 |

PT1/2 |

PT3/8 |

PT1/2 |

PT3/4 |

PT1 |

|||||||||

Filter Element Accuracy |

40um Or5μm |

|||||||||||||||||

Adjustment Range |

Automatic And Differential Drainage:0.15~0.9MPa(20~130psi);Hand Drain Type:0.05~0.9MPa(7~130psi) |

|||||||||||||||||

Maximum Working Pressure |

1.0MPa(145psi) |

|||||||||||||||||

Proof Pressure |

1.5MPa(215psi) |

|||||||||||||||||

Using Temperature Range |

5~70℃ |

|||||||||||||||||

Filter cup Capacity |

10CC |

40CC |

80CC |

230CC |

||||||||||||||

Oil cup Capacity |

25CC |

75CC |

160CC |

380CC |

||||||||||||||

Recommended Lubricating Oil |

ISOVG32Or Equivalent Oil |

|||||||||||||||||

Weight |

430g |

980g |

1950g |

4320g |

||||||||||||||

CompoNent |

Pressure Regulating Filter |

GFR200-06 |

GFR200-08 |

GFR300-08 |

GFR300-10 |

GFR300-15 |

GFR400-10 |

GFR400-15 |

GFR600-20 |

GFR600-25 |

||||||||

Oil Feeder |

GL200-06 |

GL200-08 |

GL300-08 |

GL300-10 |

GL300-15 |

GL400-10 |

GL400-15 |

GL600-20 |

GL600-25 |

|||||||||

Copyright © 2026 Youboli Pneumatic Technology Co., Ltd. All right reserved - Privacy policy