Hurtige links

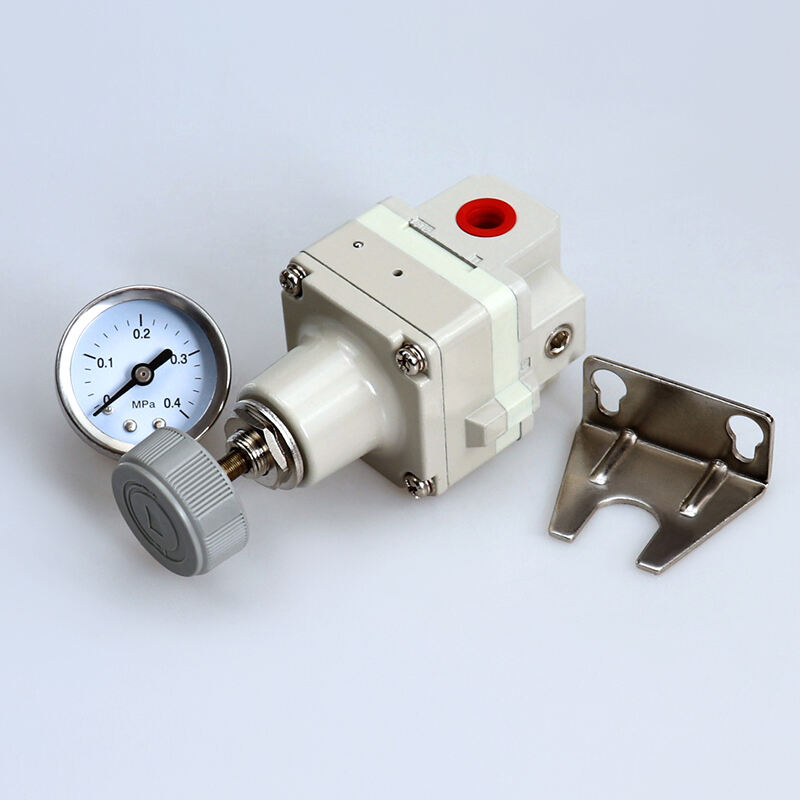

Højpræcis trykreguleringsventil til justering af gastryk | IR2000/IR2010/IR2020-02BG trykreguleringsventil med digital visning

Copyright © 2026 Youboli Pneumatic Technology Co., Ltd. Alle rettigheder forbeholdes - Privatlivspolitik