مقدمة: هل أنظمة الهواء الخاصة بك جاهزة للثورة الصناعية القادمة؟

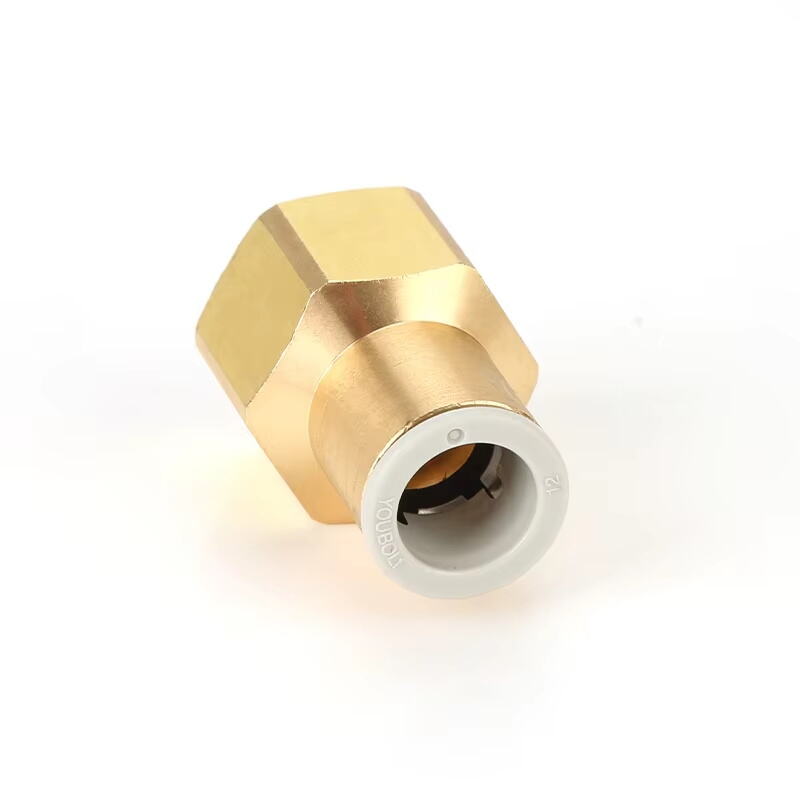

إن بيئة الأتمتة الصناعية تشهد تغيرًا جذريًا. ظهور الصناعة 4.0 والروبوتات التعاونية (الكوبوتات) والآلات المدمجة ذات الكثافة العالية يتطلب المزيد من الأداء من كل مكون - خاصة من عالم الوصلات الذي غالبًا ما يتم تجاهله. الاتصالات النيوماتيكية لعقود، اعتمد القطاع على وصلات قياسية جاهزة. ولكن ماذا يحدث عندما يقتصر تصميمك على مساحة بحجم مكعب السكر؟ أو عندما تحتاج جهازك الطبي إلى موصل يمكن تعقيمه مرارًا وتكرارًا دون أن يفشل؟

الجواب يكمن في اتجاهين قويين ومتصلين ببعضهما البعض: التصغير و التصنيع حسب الطلب ليست هذه مجرد مصطلحات رنانة؛ بل هي استجابات جوهرية للاحتياجات المتغيرة في التصنيع الحديث. الاستمرار في استخدام حلول الاتصال التقليدية قد يؤدي إلى تنازلات في التصميم واستخدام غير فعال للمساحة الثمينة وعدم الوفاء بالمتطلبات الصارمة التي تفرضها الصناعات المتقدمة.

يُلْقِي هذا المقال نظرة على مستقبل تكنولوجيا الهواء المضغوط. سنستعرض كيف تُعيد القيادة المستمرة نحو تصميمات أصغر وأكثر ذكاءً وتحديدًا شكل ما يمكن تحقيقه عبر الأنظمة المُدَفَعة بالهواء. سنتناول التطورات الهندسية التي تُمَكِّن هذا التحوُّل، والفوائد الملموسة بالنسبة لتطبيقاتك، وقبل كل شيء، كيفية التنقل بفعالية في عملية شراء أو تطوير الموصل المخصص أو المصغر المثالي الذي يمنح منتجك ميزة تنافسية حاسمة.

السبب: القوى الدافعة وراء التصغير والتخصيص

طلب السوق على الحلول الأذكى والأصغر والأكثر تحديدًا

إن الدفع نحو اتصالات هوائية متقدمة لا يحدث في فراغ. بل يقوده اتجاهات كبرى قوية عبر الصناعات العالمية:

انتشار الروبوتات التعاونية والماكينات المدمجة: تعمل الروبوتات الصناعية التقليدية داخل خلايا كبيرة ومغلقة. أما الروبوتات التعاونية (Cobots)، التي صُمّمت للعمل جنبًا إلى جنب مع البشر، فهي أصغر حجمًا وأخف وزنًا، وتحتاج إلى مكونات هوائية مدمجة بنفس القدر من الكفاءة دون التفريط في الأداء. لا يمكن تركيب وصلات كبيرة الحجم على ذراع الروبوت التعاوني.

المساحة لها قيمة عالية: في قطاعات مثل تصنيع أشباه الموصلات، والتشخيص الطبي، وتجميع الإلكترونيات، يُعد كل مليمتر مربع من مساحة الماكينة ذا قيمة استثنائية. تسمح الوصلات المصغرة للمهندسين بدمج وظائف أكثر ضمن مساحة أصغر، مما يعزز إمكانيات الماكينة دون زيادة حجمها.

-

الحاجة إلى التطبيق -أداء خاص: الوصلات القياسية مناسبة للتطبيقات القياسية. ولكن ماذا عن:

البيئات ذات النظافة العالية (الغذاء والصيدلة): وصلات تتحمل دورات التنظيف التعقيم المتكررة (CIP/SIP) دون أن تتآكل أو تفشل.

البيئات القاسية (الصناعات الكيماوية والبحرية): وصلات مصنوعة من سبائك أو بوليمرات خاصة تقاوم المواد الكيميائية العدوانية أو مياه البحر.

تطبيقات منخفضة الضجيج: موصلات مصممة بمسارات تدفق داخلية تقلل من توربلنت الهواء ومستويات الصوت.

ما المقصود بتحديد حقبة جديدة في الاتصالات الهوائية؟

ما وراء المعيار: ما المقصود بـ التصغير والتخصيص؟

-

التصغير هي تخصص هندسي يركز على تقليل المقياس المادي للمكونات مع الحفاظ على، أو حتى تحسين، أدائها الوظيفي. هذا لا يتعلق فقط بصنع نسخة أصغر من قطعة قياسية، بل يشمل أيضًا:

موصلات دقيقة: موصلات مصممة لأنابيب بأقطار تصل إلى حد أدنى مقداره 1/16" (1.5 مم) أو حتى 1 مم ، تعمل ضمن نطاقات الضغط الصناعية الكاملة (مثلاً، 100 رطل/بوصة مربعة أو أكثر).

مواد متقدمة: استخدام مواد خفيفة الوزن وقوية مثل مادة PEEK (بولي إيثر إيثر كيتون) والصلب المقاوم للصدأ الدقيق لضمان سلامة هيكلية على مقياس صغير جدًا.

تصميم توفير المساحة: تصميمات منخفضة الارتفاع، ومثبتة بشكل مسطح، وزاوية قائمة تندمج بسلاسة في المساحات الضيقة.

-

التصنيع حسب الطلب هو عملية تعديل تصميم المكون أو مادته أو وظيفته لتلبية المتطلبات الدقيقة لتطبيق معين. ويمكن أن يشمل ذلك من مجرد تغيير اللون إلى إعادة تصميم كاملة من الألف إلى الياء. ويشمل ذلك:

التخصيص الهندسي: تغيير مواقع المنافذ، أو أنواع الخيوط، أو العوامل الشكلية العامة لتتناسب مع أنبوب جمع أو كتلة آلة معينة.

تخصيص المادة: تحديد مركبات خاصة لحلقات O (على سبيل المثال، مادة Viton® المعتمدة من إدارة الأغذية والعقاقير FDA) أو مواد للجسم (على سبيل المثال، مادة PVDF المقاومة للمواد الكيميائية) لضمان التوافق.

تخصيص وظيفي: دمج ميزات إضافية مثل التحكم في التدفق المدمج، أو أجهزة استشعار الضغط، أو صمامات الفصل السريع مباشرةً في الوصلة.

التقنيات التي تجعل هذا ممكنًا

تقود هذه الثورة عدة تقنيات رئيسية:

تصنيع CNC بدقة: يمكن لماكينات CNC ذات المحاور الخمسة إنتاج هندسات معقدة وصغيرة للغاية بتسامح يُقاس بالميكرون.

التصنيع الإضافي (الطباعة ثلاثية الأبعاد): لإنشاء نماذج أولية سريعة للتصاميم المخصصة، مما يسمح باختبار الوظائف وتكرار التصميم خلال أيام وليس أسابيع. كما يمكّن من تحقيق هندسات قناة داخلية مستحيل تحقيقها باستخدام التقنيات التقليدية للتشغيل.

ميكانيكا السوائل الحاسوبية (CFD): تُستخدم لمحاكاة وتحسين مسار تدفق الهواء الداخلي لموصل صغير الحجم، مع تقليل الانخفاض في الضغط والاضطرابات الهوائية حتى في المساحات المحدودة.

كيفية: اجتياز الطريق نحو الحلول المخصصة والأصغر حجمًا

دليل خطوة بخطوة لتحديد الموصل المثالي لك

الانتقال من حل قياسي إلى حل مخصص أو صغير الحجم يتطلب شراكة تعاونية مع المورد الخاص بك. إليك الطريقة المناسبة لذلك:

-

حدد متطلبات التطبيق بدقة:

-

قم بإنشاء ورقة مواصفات مفصلة تتضمن:

الأداء: الضغط التشغيلي، معدل التدفق (قيمة Cv)، والانخفاض الأقصى المسموح به في الضغط.

البيئية: مدى درجة الحرارة، الوسيط (هواء، غازات أخرى؟)، التعرض للمواد الكيميائية أو الأشعة فوق البنفسجية أو التعقيم.

فيزيائي: المساحة القصوى المسموح بها، قيود الوزن، والاتجاهات المطلوبة للمداخل.

التنظيم: الشهادات اللازمة (ISO 9001، FDA، USP Class VI، ATEX).

-

-

الشراكة مع المُصنِّع المناسب:

ابحث عن مورد لديه سجل إثبات التصميم من أجل القابلية للتصنيع (DFM) . يجب أن يكون قادرًا على مراجعة تصميماتك الأولية واقتراح تعديلات تُحسّن الموثوقية وتقلل من تكلفة الإنتاج.

قيّم القدرات الأولية . هل يمكنهم توفير نماذج أولية مطبوعة ثلاثية الأبعاد أو منحوتة للاختبار السريع؟

قيّم الخبرة الهندسية . يجب أن يطرحوا أسئلة مفصلة حول تطبيقك لفهم المشكلة بشكل كامل.

-

التعاون في مرحلة التصميم:

هذا عملية تكرارية. كن مستعدًا لمراجعة الرسومات الفنية (نماذج CAD) والتعليق عليها.

وثق بخبرة الشريك في اختيار المواد وتقنيات التصنيع.

-

اختبار النماذج الأولية بدقة:

لا تتجاوز هذه الخطوة أبدًا. قم باختبار النماذج الأولية داخل الجهاز الفعلي أو بيئة محاكاة.

قم باختبار دورة الحياة حتى الفشل للتأكد من أن التصميم يلبي متطلبات المتانة.

المميزات والعيوب: تقييم الاستثمار

| وجه | المزايا | العيوب |

|---|---|---|

| الأداء |

الوظيفة المُحسّنة: مصممة بدقة لتلبية احتياجات تطبيقك. كفاءة محسّنة: تقليل فقدان الضغط واستخدام المساحة إلى الحد الأدنى. تحسين الموثوقية: تم تصميمه ليناسب بيئتك التشغيلية الخاصة. |

|

| التصميم والابتكار |

يُطلق العنان للابتكار: يُمكّن من تصميم منتجات مبتكرة. الميزة التنافسية: يوفر ميزات لا تتمكن الحلول الجاهزة من تقديمها. الوظائف المتكاملة: يمكنه الجمع بين وظائف متعددة في جزء واحد. |

تكلفة أولية أعلى: التكاليف الهندسية غير المتكررة (NRE) للتصميم والتجهيز. فترة الانتظار أطول: يستغرق التصميم والنموذج الأولي وقتًا قبل الإنتاج. |

| سلسلة التوريد |

تجميع مبسط: غالبًا ما يقلل من عدد الأجزاء ووقت التجميع. حماية الملكية الفكرية: التصاميم المخصصة تكون فريدة لمنتجك. |

الاعتماد على المورد: أنت مرتبط بمصنّع واحد فقط لتلك القطعة. |

الحكم: يُبرر الاستثمار في التخصيص والتصغير عندما يُحلّ تحدي تصميم حيوي، أو يعزز قابلية تسويق منتجك، أو يقدّم تحسينًا ملحوظًا في الأداء لا تستطيع المكونات القياسية تقديمه. بالنسبة للمعدات ذات القيمة العالية، فإن الفوائد طويلة الأمد تفوق في الغالب التكاليف الأولية للتطوير.